Cell-Based Cocoa, Genetically Modified Bananas, and Bill Gates Bets on Alt Fats

Also: Scientists developed a hybrid food combining animal cells cultivated within rice grains

Hi, thanks for being here!

Here’s my favourite quote that I came across this week:

"I predict the New York Times will be proved embarrassingly wrong on this one. Just because a better future is hard to build, doesn't mean we should stop. For me, I'll throw my lot in with the determined, the visionary."

That was Chris Anderson’s response to a recent NYT article titled "The revolution that died on the way to dinner," which criticised the cultivated meat industry.

Alright, let’s dig into the latest developments in biotech-enabled food innovation! 🍽

BIO BUZZ

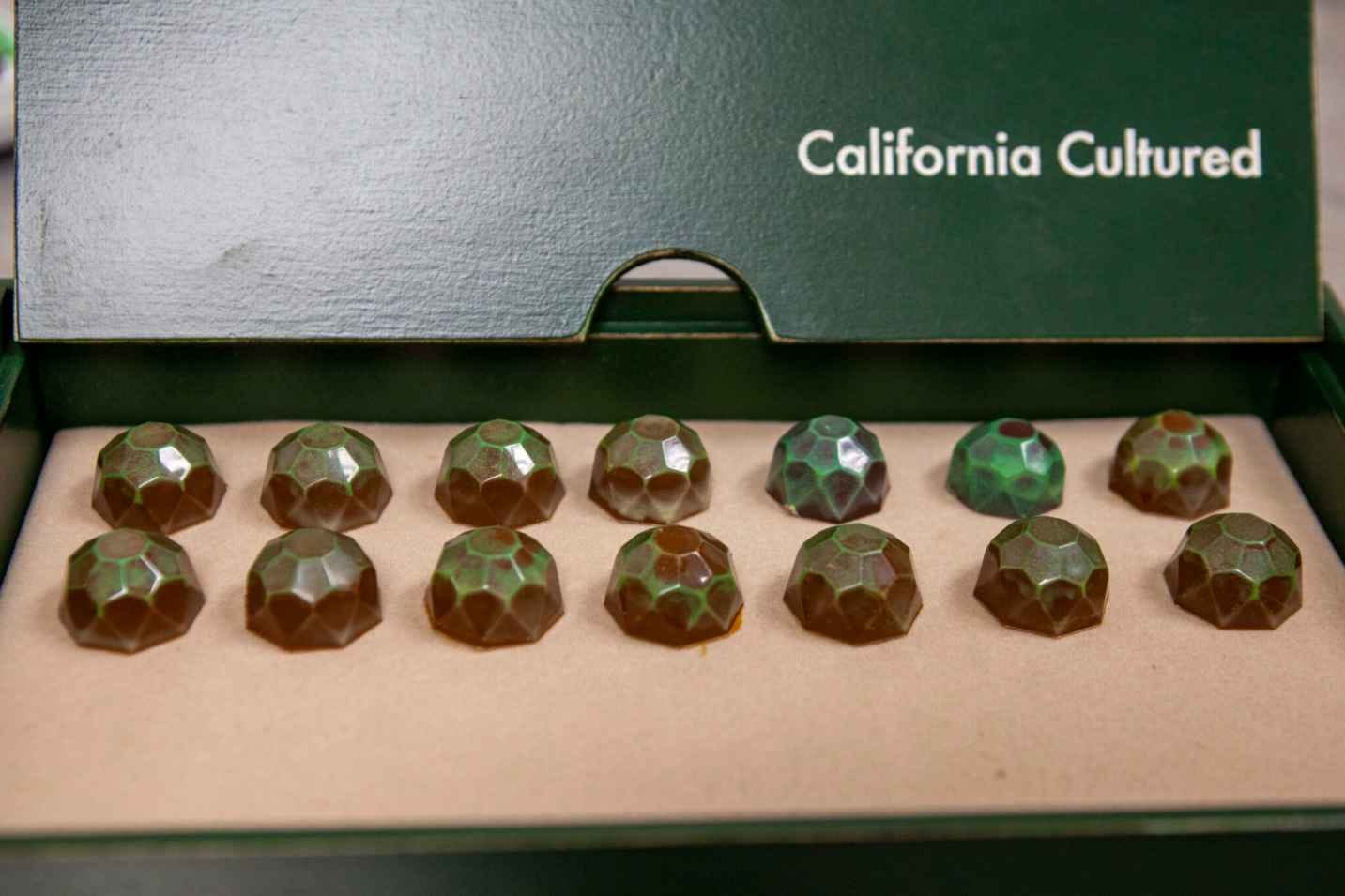

🍫 California Cultured formed a 10-year commercial partnership with Japanese chocolate giant Meiji for cell-based cocoa products

The collaboration marks the ‘first time’ cell-cultured chocolate will enter the market globally. It addresses the growing supply gap in the cocoa industry due to challenges such as deforestation, climate change, and human rights issues.

The West Sacramento-based food tech startup's production process involves harvesting cells from cocoa plants and growing them in fermentation tanks. This method significantly reduces GHG emissions and offers a sustainable alternative to traditional cocoa production.

The partnership is targeting a late 2024 launch for products in the nutraceutical, chocolate, and better-for-you snack markets. The pricing will be “very competitive with high-value nutritional products on the market” in the categories mentioned.

🧀 New Culture has obtained the ‘world's first’ self-affirmed GRAS status for animal-free casein

The precision fermentation company is the only precision-fermented casein producer authorised to sell casein as a food ingredient in the US and plans to notify FDA of its self-GRAS (Generally Recognized as Safe) determination soon.

New Culture's mozzarella is designed to mimic conventional cheese in melting, stretching, and browning, and is made from powdered casein, water, fat, sugar, vitamins, and minerals.

The company's animal-free casein can produce cheese for 25,000 pizzas per batch, with plans to scale up and reduce manufacturing costs by 80% to reach price parity with conventional mozzarella in 3 years.

🤝 Döhler partner with Superbrewed Food to produce high-protein postbiotic ingredient from biomass fermentation

Superbrewed Food's non-GMO bacterial biomass has a high protein content (85%), a PDCAAS (protein digestibility) score of 0.91 (which ranks higher than most plant proteins), and rich levels of B vitamins and minerals like iron and zinc.

Superbrewed's ingredients are said to have a neutral taste and a natural white colour. They possess excellent pH and temperature stability, along with good emulsification properties. These qualities make them suitable for a wide range of products, including dairy alternatives, protein bars, and baked goods.

The partnership allows Superbrewed to focus on bringing products to market quickly, pausing plans to retrofit an ethanol plant in Minnesota for large-scale anaerobic fermentation.

🥓 MyForest Foods introduced its mycelium-based protein alternative, MyBacon, to 57 Whole Foods locations in Eastern US

The expansion brings MyForest Foods' commercial retail footprint to over 350 locations across 8 states in the United States. MyBacon is made from just 5 ingredients: mycelium, organic coconut oil, organic sugar, salt, and natural flavour.

The company opened the "world’s largest" vertical mycelium farm in 2022, supported by a $15 million venture loan. Last year, the company raised an additional $15 million in a Series A-2 funding round to scale production and increase its retail and food service presence in the eastern US.

According to co-founder Eben Bayer, next-generation products like mycelium-based MyBacon are addressing the limitations of “overhyped first-generation players” by offering simpler, more understandable ingredient lists and clearer nutritional benefits while moving the market forward

🇮🇸🇦🇺 ORF Genetics and Vow successfully conducted "first of its kind" cell-based meat tasting in Europe

The cell-based meat tasting saw various professionals taste dishes created from the cells of Japanese quail.

Among those attending was the Prime Minister and acting Minister of Food, Fisheries and Agriculture of Iceland, Katrín Jakobsdóttir, who “enjoyed” her first taste of cell-based meat at the event.

"It is clear that our food systems need to change so that we can feed a population estimated to reach 9 billion in 2040. It is also evident that we need to use innovation and technology to establish new ways of addressing the climate challenge. This is exactly what we are seeing on the tasting tables here today.” said Jakobsdóttir

🍔 MYCO is launching “Britain's greenest burgers” made from Hooba, a protein mince derived from oyster mushrooms

The Hooba burger received positive feedback at a tasting event, outperforming established brands like Linda McCartney, Beyond Burger, and Plant Pioneers in taste and sensory evaluations.

The burgers are expected to be ready by the end of March 2024, with plans for a national rollout in UK supermarkets.

Hooba, is grown in AI-controlled, vertical farms and is rich in micronutrients. The company claims its facility is the only one in the country farming and producing proteins under the same roof, ensuring zero food miles.

🚀 Bill Gates shares why he is making big bets on novel fats and oils

"Cheeseburgers are my favorite food. But I wish they weren’t, given the impact they have on the environment.". The production of fats and oils from animals and plants accounts for 7% of the world's GHG emissions.

Gates-backed Savor and C16 Biosciences innovate in environmentally-friendly fats: Savor crafts animal-free fat molecules by extracting CO2 and H2O, slashing GHG emissions and resource use. C16 develops emission-free, fermented palm oil alternatives, targeting industry-wide adoption.

Gates' investment in Savor and C16 Biosciences underscores his belief in tech's role in addressing climate change by replacing environmentally harmful animal and plant fats with sustainable alternatives that do not compromise on taste or functionality.

🍚 Scientists at Yonsei University developed cultured beef rice, a hybrid food combining animal muscle and fat cells cultivated within rice grains

The product uses a combination of rice grains, fish gelatin, and microbial transglutaminase to support cell growth, offering a more food-safe and cost-effective alternative to some other lab-grown meats.

Cultured beef rice shows an 8% increase in protein content and a 7% rise in fat content over regular rice, with distinctive flavour profiles depending on the muscle and fat content.

The research team is focusing on optimising conditions within the rice grains to further improve the nutritional profile and taste of the hybrid product. The development of hybrid rice has the potential to lead to a self-producing food kit, which could be used for space food, combat rations, and hunger relief.

🍼 TurtleTree has become the first precision fermentation dairy company to earn vegan certification

Vegan Action, the most recognised vegan certification body in the US, has given its first certification to a novel protein in its 24-year history to TurtleTree's LF+.

LF+'s certification shows TurtleTree's commitment to animal welfare and meeting consumer demands, especially given the complex interpretations around bioidentical nature and production methods of precision fermentation products.

The Singaporean startup claims that being the only vegan lactoferrin on the market, LF+ will challenge the dominance of bovine lactoferrin, offering an affordable and scalable solution to “the global shortage of lactoferrin." The company has previously said its clients are interested in purchasing $500M worth of LF+ over the next 5 years.

MACRO STUFF

🍌 Genetically modified bananas have been approved by regulators for the first time

Regulators in Australia and New Zealand have approved a genetically modified strain of the Cavendish banana, named QCAV-4, resistant to a destructive fungal disease called TR4.

The Cavendish banana replaced the Gros Michel variety in the 1950s due to susceptibility to a different Fusarium fungus strain. The introduction of QCAV-4 aims to protect the Cavendish variety from the TR4 strain, which poses a global threat to banana production.

The GM banana was developed by a team at the Queensland University of Technology by introducing a gene from a wild banana. There are plans to further enhance resistance against another fungal disease using CRISPR gene editing.

🇯🇵 New report reveals that 42% of Japanese consumers are willing to try cultivated meat or seafood products

Safety, health, and price are the top 3 factors that could influence consumers' willingness to try cultivated products. 43.7% of consumers believe Japanese government regulations are important for determining the the products.

58% of Japanese respondents are unfamiliar with 'cell-based foods', and a majority are unsure of the safety compared to conventional products.

Over 50% of men in their twenties have heard of cell-based foods, nearly 30% are interested in trying them, and 62% would eat these products if cooked.

🔒 How to properly patent your food tech innovation

Patents are a key business tool for startups, protecting them from large companies infringing on their tech. They can strengthen a startup's position, open up unforeseen opportunities, and provide a pre-emptive effect against competitors patenting the same tech.

Startups should consider filing for patents early in the development process, using the provisional patent mode. It's important to file before starting pilot sales and to focus on product claims, which are typically stronger and easier to enforce than process claims.

Startups need to consider the geography of filing, the market size, and the location of competitors. They should also evaluate the enforceability of the patent, especially for process patents, and weigh the pros and cons of filing a patent versus keeping a trade secret.

BIO BUCKS

🛠 GEA announces €18M investment in technology centre for alt proteins to support the industry's anticipated growth

The facility in Wisconsin will focus on piloting microbial, cell-based, and plant-based food techs, with construction beginning in spring 2024 and opening anticipated in 2025.

The centre aims to bridge the market gap for industrial-scale production of alt proteins and support the industry's anticipated growth. A GEA survey last year found that chefs expect a quarter of meals to incorporate alt proteins by 2040.

The global engineering systems leader’s new centre will offer process testing, and validation, and plans to foster biotech expertise through training programs within the 10,000 m2 facility.

🇰🇷 Simple Planet raised ₩8B in a pre-Series A funding round to optimise its tech for its powdered cultivated meat ingredient

The South Korean startup focuses on creating powdered and paste forms of cultivated meat ingredients, including proteins and unsaturated fats, instead of creating finished products. The ingredients are said to be highly versatile, helping to improve the flavour and nutritional structure of conventional proteins.

Simple Planet has developed 13 floating cell lines from various sources such as cows, chickens, pigs, ducks, and fish. They have developed a probiotics-based serum-free edible culture medium, which reduces production costs by 1/60th compared to using fetal bovine serum.

The company is expanding its global footprint, having established strategic partnerships with firms like Plug and Play and S&S Lab. Last year, the startup teamed up with Pulmuone to co-produce hybrid meat products, with a targeted 2025 launch.

🍄 ENOUGH extends its agreement with Cargill, including a commercial deal for ABUNDA mycoprotein and a Series C investment

ENOUGH uses biomass fermentation to produce ABUNDA, which provides all 9 essential amino acids and dietary fiber, featuring a neutral taste for versatility in various food applications.

The collaboration will allow ENOUGH to scale more quickly in Europe and beyond by benefiting from Cargill’s global presence and feedstock tech expertise. ENOUGH’s production facility, co-located with Cargill in Netherlands, benefits from Cargill’s glucose syrup, supporting the zero-waste production of ABUNDA.

ENOUGH's protein production facility initially can produce 10,000 tonnes of protein each year, with plans to double this output by 2025. By 2033, the company aims to have produced more than a million tonnes in total.

“The alternative protein market is a multi-billion-dollar opportunity, and efficiency will come from collaboration with partners such as Cargill to leverage existing demand and supply chain to gain scale.” - Jim Laird, co-founder of ENOUGH

🇧🇷 Cellva Ingredients raised R$6.5M to advance developing and producing cultivated animal ingredients, starting with pork fat

Cellva Ingredients, the first startup in Brazil to develop and produce cultivated animal ingredients, has developed a tech that can produce pork fat in just 21 days. Traditional pork fat production takes around 24 months.

Cellva's tech allows for the customisation of fats to be healthier through a non-GMO modulation process: less saturated fat, anti-inflammatory, antioxidative, and better digestibility features.

With plans to expand its production capacity, Cellva aims to introduce products by Q4 2024 or Q1 2025, depending on the regulatory approval in Brazil.

🇩🇪 Pacifico Biolabs announced a $3.3M oversubscribed pre-seed round to scale its mycelium-based whole-cut seafood alternatives

The Berlin-based biotech startup plans to use the funding to improve and scale its “unique” biomass fermentation process and expand its team by hiring a CTO and chief of staff.

Founded in 2022, Pacifico Biolabs aims to offer better seafood alternatives through a fermentation process that cultivates multiple microorganisms, including mycelium, and uses industry’s side streams as feedstock.

The company's fermentation process is said to produce highly nutritious and versatile biomass suitable for meat and fish alternatives as well as functional foods, with plans to launch products across Europe.

SOCIAL FEAST

🤩 Impeccable, revolutionary, and ethical: Tasting UPSIDE Foods’ cultivated chicken, marking first meat consumption in over 30 years

Heather described UPSIDE Foods’ cultivated chicken as “impeccable—succulent, moist, and perfectly textured.” and adds that “It was, in every aspect, chicken as it should be, yet without the ethical and environmental toll of traditional poultry farming.”

The traditional meat industry, known for its use of antibiotics, crowded conditions, and ethical concerns related to animal welfare, is a method of production that many people are eager to move away from.

Heather (an investor in UPSIDE) views this tech as a ray of hope for ethical eating and believes it represents a future where taste, ethics, and environmental impact align without compromising values.

Read full post on LinkedIn - Heather Courtney

👏🏾 The delicious promise of cultivated meat in our fight for a sustainable future

He believes that cultivated meat has a significant role in the future of food, offering a kinder and more sustainable option without sacrificing taste or human meat consumption habits.

Chris criticised a New York Times article, titled ‘The Revolution That Died on Its Way to Dinner’, for being cynically dismissive of the potential for cultivated meat to revolutionise how humans are fed.

He praised UPSIDE for its clean and transparent production facilities, contrasting them with the hidden and unethical conditions of traditional chicken farming.

“I predict the New York Times will be proved embarrassingly wrong on this one. Just because a better future is hard to build, doesn't mean we should stop. For me, I'll throw my lot in with the determined, the visionary.”

Read full post on X - Chris Anderson

🌏 Snapshot of global regulatory approvals for precision fermentation ingredients

See full post on LinkedIn - Laurène Bajard

MORE ON BETTER BIOECONOMY

🚀 10 notable developments in the fermentation-based food industry last month

That’s a wrap. Thank you for taking the time to read this issue!

Are you new here?

Know anyone else who would dig this newsletter?

Eshan, I LOVE that quote by Chris Anderson responding to the NYT. It is inconceivable to me how journalists can make such bold proclamations, yet are rarely held accountable when they are wrong (as is true so often).

Ultimately, the lab-grown food industry (especially with cultivated meats), once they perfect the taste/texture/quality dimensions, will need to focus on costs. One of the costliest inputs to cultivate lab-grown proteins are growth factors. Are you familiar with Future Fields? I've been watching the company and they seem to be on a path to dramatically reduce the input cost with their growth factors.