€290M for European Alt Protein Research, World’s First Food-Grade Cell Feed Facility, and Egg Proteins From Potatoes for Baking

Also: Time's Best Inventions of 2024 featured Meatable’s cultivated pork

Hey, welcome to issue #81 of the Better Bioeconomy newsletter. Thanks for being here!

If you’re an agrifood tech founder, investor, or someone working on tech-based solutions for sustainable food systems, I’d love to connect. I started this newsletter to meet folks with similar interests, so feel free to reach out to chat on LinkedIn or hop on a call—I’m always happy to discuss ideas and opportunities! 🙂

Now, let’s dig into the latest developments in biotech-enabled agrifood businesses and breakthroughs! 🍽

BIO BUZZ

📈 Alt protein research in Europe attracted a record-high €290M in funding in 2023

European research on alt proteins expanded notably, with 26% of all published studies in the field emerging in 2023 alone (472 papers). Since 2010, the UK has led in research output with 255 papers, followed by Germany (243) and the Netherlands (199).

Denmark led with €96M in investments, showcasing a strong commitment from Nordic countries, which collectively funded a fifth of Europe’s total. The UK followed with €90M, largely facilitated by the UK Research and Innovation agency's establishment of research hubs.

Research funding targeted plant-based proteins (39%) as the largest category, followed by cross-cutting studies involving multiple protein alternatives (31%). Fermentation received 21%, and cultivated meat, although gaining interest, was allocated 10% of funds.

Source: Green Queen

🇳🇱 Nutreco launched the ‘world’s first’ facility dedicated to food-grade powder production for cell feed in the Netherlands

CEO David Blakemore underlined that a key challenge for cultivated proteins is developing cost-effective and sustainable feeding solutions for cells, which Nutreco aims to address by producing affordable cell culture media.

Emeline Fellus, Senior Director of Agriculture and Food at the World Business Council, noted that current food systems prioritize efficiency and high caloric output without considering sustainability. Given today’s resource constraints and environmental concerns, this model is becoming increasingly outdated.

Fellus called for a shift in protein production and consumption, recommending a diversified approach that balances traditional animal proteins with environmentally friendlier alternatives to meet growing demands sustainably.

Source: Cell Base

🍞 PoLoPo partnered with CSM Ingredients to produce egg protein ovalbumin using potatoes for the baking industry

Ovalbumin is a key protein in baking due to its foaming, gelation, and water-binding properties. Frequent avian flu outbreaks have disrupted egg supply chains, creating volatility in egg prices.

PoLoPo’s molecular farming-based protein seeks to ensure price stability and reliable availability. By optimizing the Israeli startup's potato-based ovalbumin for commercial baking, the collaboration aims to match traditional egg protein's functionality.

Luxembourg-based CSM Ingredients serves the food industry in over 100 countries. It’s supported by 9 manufacturing plants, 9 product development centres, 5 innovation centres, and a global open innovation hub.

Source: vegconomist

🧬 Ohalo launched the ‘world’s first’ self-fertile Nonpareil almond, eliminating the need for pollenizer trees

The FruitionOne variant addresses challenges in almond farming, including the costs and complexities associated with pollenizer trees and the dependency on commercial bees for pollination. The breakthrough could cut pollination costs by >50% and ensure higher yield consistency.

With FruitionOne’s self-fertile feature, farmers can expect improved profitability with up to a 30% increase in per-acre profit. This increase comes from more efficient land use (fewer pollenizer trees), lower labour costs due to streamlined harvests, and decreased reliance on costly bee hives.

FruitionOne’s adoption supports more sustainable almond production. By increasing yield per acre, it can reduce water, land, and energy requirements per almond, lowering carbon emissions and dust production associated with traditional almond farming methods.

Source: PR Newswire

🤝 Revo Foods and Paleo joined forces with €2.2M EU funding to develop realistic, animal-free salmon alternatives

The project focuses on developing a salmon-specific heme that can enhance the sensory experience of Revo Foods' 3D-printed salmon fillets, making them closer in taste and appearance to real fish.

Paleo’s precision-fermented heme is used in various plant-based products, including beef and chicken alternatives, to recreate typical animal products' taste, colour, and aroma. This technology is now being tailored to satisfy seafood enthusiasts.

If regulatory and development milestones are met, Revo’s Robin Simsa hopes to have a prototype in 2 years and to launch within 5 years. He envisions that projects like this will inspire broader innovation in the alt protein sector.

Source: vegconomist

☢️ Cultivated seafood pioneer Umami Bioworks introduced a pathogen detection tool targeting safety and quality in the seafood industry

The Arbiter tool’s nucleic-acid-based technology allows it to identify pathogens across 800 targets in a single run, producing reliable and precise results in less than 6 hours. The streamlined process needs only 15 minutes of preparation time to analyze up to 50 samples.

By keeping the cost below $1 per test target, Arbiter offers a cost-effective solution, making pathogen diagnostics more accessible for smaller-scale and larger seafood businesses. This affordability, combined with reduced labour requirements, has the potential to “democratise” pathogen detection.

Beyond food safety, Arbiter can help protect ecosystems by identifying harmful pathogens in aquaculture. This could save fish populations like salmon, shrimp, and tilapia from disease outbreaks and reduce economic losses due to infections.

Source: Green Queen

🙌🏾 Time's Best Inventions of 2024 featured Meatable’s cultivated pork and Brightseed’s AI platform for functional plant-based ingredients

Meatable’s Opti-ox technology enables cultivated pork to be produced in just 4 days, significantly faster than competitors, using pluripotent stem cells (PSCs) that naturally multiply rapidly.

Brightseed’s Forager platform uses AI to identify bioactive compounds in plants, building a library of over 7 million compounds linked to health benefits for food innovation.

Other alt protein companies like Impossible Foods, Perfect Day, and Upside Foods have previously been honoured on Time's list, highlighting the growing recognition of sustainable food technologies.

Source: Green Queen

⚡️ More buzzes

🍄 Finnish startup Enifer has applied for EU approval for its Pekilo mycoprotein as a novel food, marking the first such application by a Nordic mycoprotein company. Enifer aims to expand beyond Europe, targeting approvals in Singapore, the US, and the UK. (Green Queen)

🥛 Bon Vivant unveiled ‘Europe’s first’ peer-reviewed LCA for precision-fermented milk proteins. The French startup's technology cuts greenhouse gas emissions by 72%, water use by 81%, and land use by 99%. (Cell Base)

BIO BUCKS

💶 6 food tech startups received funding at Next Bite, EIT Food's flagship event, to test their technologies and fast-track market entry

Startups received funding amounts ranging from €20,000- €50,000. Six of these startups focus on alt proteins, cell-based solutions, and fermentation-based ingredients to address climate and food system challenges.

The largest grant (€50,000) went to Esencia Foods for its mycelium-based seafood alternatives. Other key recipients include Clean Food Group, developing palm oil substitutes from bread waste, and Quest Meat, innovating in cultivated meat with its Neutrix material.

This funding allows the startups to collaborate with EIT Food's European partner network, which includes universities and research centres, to refine and validate their technologies in preparation for market readiness.

Source: Green Queen

💰 Big Idea Ventures’ Global Food Innovation Fund II invested in 6 startups focusing on cultivated meat, fermentation, and gut health

The fund builds on Big Idea Ventures' successful New Protein Fund I, expanding investments in proteins, fats, and sustainable ingredients. Supported by major food corporations like AAK and Buhler, the fund aims to improve food security and sustainability.

Meatosys, BiomeMega, Nalca Biotech, and Renew Food are developing solutions such as on-farm cultivated meat production, sustainable omega fatty acids, modular fermentation, and protein-based flavours for plant-based meats.

The other two startups, NanoInGreen and Future Biome, focus on enhancing gut health through probiotic ingredients with high absorption and advanced prebiotics that address microbiome-related health issues.

Source: Cell Base

🐷 Meatable and Sticta received a grant from GFI to create a detailed model of pig cells to support cultivated meat research

Sticta Biologicals and Meatable, supported by Merken Biotech and the University of Chile's Center for Mathematical Modeling, will develop an advanced genome-scale metabolic model of pig cells to optimise porcine cell nutrition and improve cultivated pork production efficiency.

By employing -omics data (genomic, proteomic, etc.) from time-course studies, the team will refine a proteome-constrained metabolic model that accurately represents the cells' metabolic needs during their growth phases.

This model may help extend the growth phase duration and speed up cell population doublings, resulting in higher yields and reduced variability in cultivated meat production.

Source: Cell Base

🌾 SugaROx received Innovate UK funding to develop biostimulants for wheat in collaboration with Rothamsted Research and Oxford University

Based on trials across multiple countries, the T6P biostimulant has shown potential yield increases of 5%- 22% in ideal conditions and 4%- 14% under drought stress.

The project draws on over 25 years of T6P research, focusing on optimizing biostimulant use based on genotype, environment, and management (GxExM) factors.

ADAS, a leading UK agricultural consultancy, will oversee 40 field trials in the UK over the next four years in partnership with local farmers to support large-scale adoption.

Source: iGrow News

GEEK ZONE

🔬 Serum-free co-culture system with growth factor-secreting cells and cyanobacteria holds potential for sustainable cultivated meat production

Cyanobacterium (Synechococcus sp. KC0110) helped maintain an optimal culture environment by converting lactate and ammonium into nutrients like pyruvate, indirectly conserving glucose levels for RL34 liver cells. This waste-clearing action prevents the build-up of cytotoxic levels of lactate and ammonium.

Results showed that RL34 and KC0110 co-culture mediums could triple the growth rate of C2C12 myoblasts compared to standard RL34 monoculture medium. This co-culture medium also offers improved nutrient composition and lower waste levels, optimizing muscle cell proliferation.

This co-culture system, which focuses on reducing reliance on animal products and lowering production costs, represents a step toward scalable, sustainable meat alternatives.

Source: Nature

🌽 Hydrolysis products of agricultural waste serve as microbial fertilizer enhancers to promote the growth of maize crops

Agricultural waste hydrolysis generates organic acids that support Bacillus amyloliquefaciens SQR9 in colonizing maize roots, helping plant growth. Hypoxic hydrolysis improves SQR9's ability to support maize by enhancing root interaction.

Optimal hydrolysis conditions vary by waste type: mushroom bran works best at pH 8.0, 40°C, with a 15% inoculum for 168 hours, while tobacco waste requires pH 6.0, 40°C, 15% inoculum, and 144 hours.

Dilutions of 2000-fold for tobacco and 5000-fold for mushroom bran hydrolysates showed the best results in root colonization and maize growth under greenhouse conditions.

Source: Frontiers

😋 Engineered yeast platform achieved a 5x increase in the concentration of natural aldehyde flavours

Researchers engineered S. cerevisiae (yeast) to address consumer demand for natural aldehydes in flavours and fragrances, such as (2E)-nominal, traditionally obtained via costly plant extraction or synthetic methods.

The engineered yeast used enzymes LOX (lipoxygenase) from Nicotiana benthamiana and HPL (hydroperoxide lyase) from melon (Cucumis melo) to convert polyunsaturated fatty acids (PUFAs) into aldehydes.

Optimization techniques included gene expression tuning, reaction condition enhancements, and cell permeabilization, collectively improving yield to about 9%. This marked a 5.5-fold increase in concentration and improved scalability.

Source: Applied Microbiology and Biotechnology

🥒 Bacillus velezensis and its bio-organic fertilizer significantly inhibit cucumber wilt and enhance cucumber growth

The study identified the efficacy of Bacillus velezensis Bv-116 in inhibiting Fusarium oxysporum, a pathogen causing cucumber wilt. With an inhibition rate of 84.93%, Bv-116 showed a broad-spectrum effect on soil-borne pathogens.

B. velezensis Bv-116 releases volatile organic compounds (VOCs), proteases, and cellulases. These substances disrupt pathogen cell membranes, causing loss of cell contents and reducing fungal growth rates, effectively limiting pathogen spread.

In a controlled greenhouse environment, plants treated with Bv-116 and its bio-organic fertilizer saw an increase of up to 520% in root dry weight. They demonstrated enhanced chlorophyll content, indicating an improvement in photosynthetic capacity.

Source: Frontiers

POST & POD

🇮🇳 Takeaways from the roundtable discussion on the future of food in India at the International Knowledge Millennium Conference

There’s a strong call for a comprehensive protein literacy policy aimed at helping consumers understand their protein requirements. This initiative would also assess whether smart proteins should stand out as a separate category.

Ensuring health and nutrition remain at the forefront is vital for the success of novel food systems, making sustainable choices more appealing and beneficial for consumers.

For now, cultivated and fermented proteins will be regulated as ‘Novel Products’ since a dedicated regulatory body has yet to be established, which will affect the industry's growth pathway.

Source: Kamalnayan Tibrewal

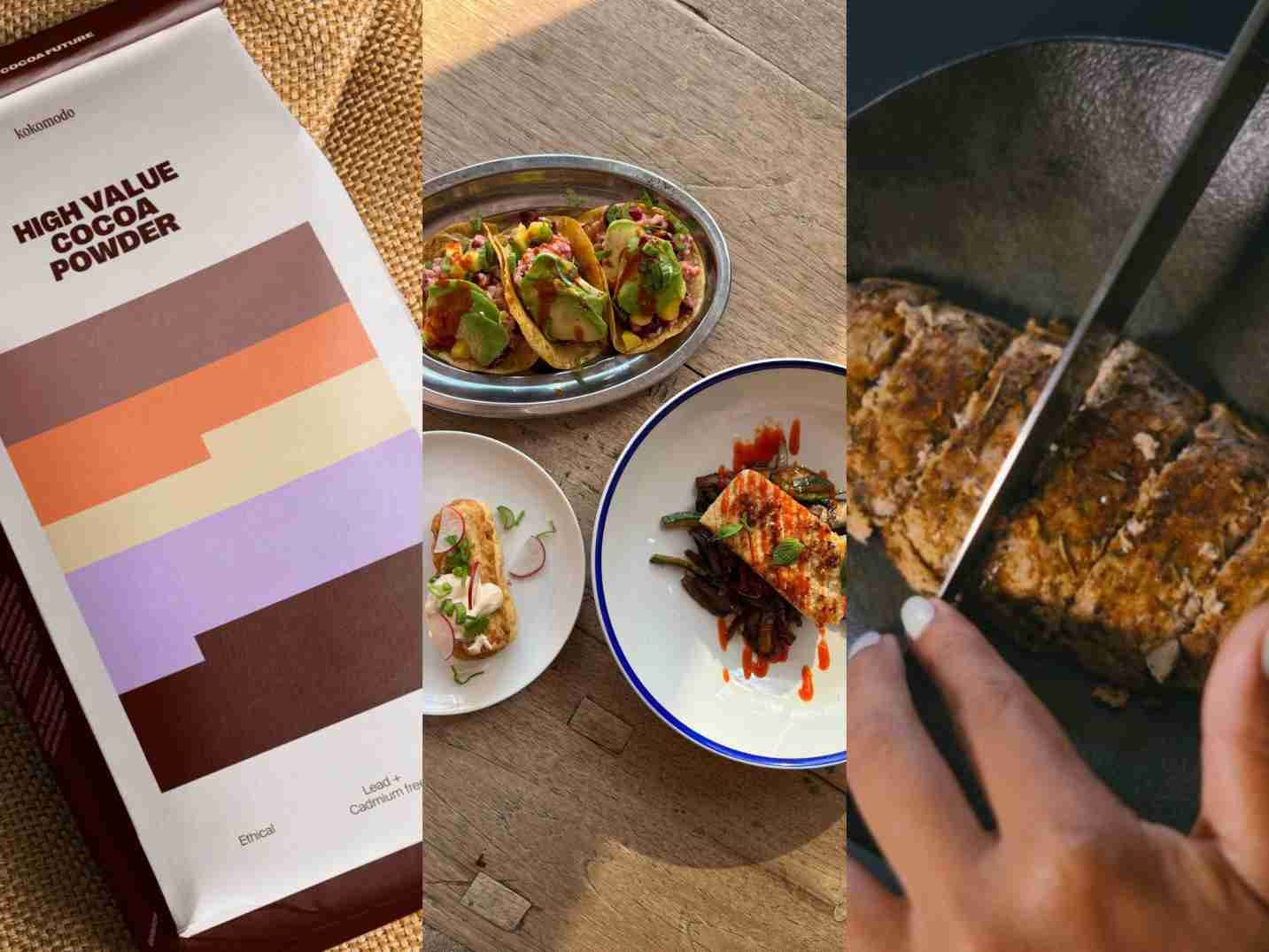

🎧 California Cultured’s Alan Perlstein on fixing the chocolate industry by growing cocoa cells in bioreactors

APAC AGRI-FOOD INNOVATION SUMMIT

🤝 Meet 1000+ global leaders who are accelerating climate-adaptation strategies for food security in Asia

Better Bioeconomy is excited to be a media partner for the Asia-Pacific Agri-Food Innovation Summit at Marina Bay Sands on November 19-21!

As the anchor event of Singapore International Agri-Food Week, in collaboration with Temasek, the Singapore Food Agency, and Enterprise Singapore, the Asia-Pacific Agri-Food Innovation Summit will bring together over 1000 global leaders to identify the strategic priorities as we build greater capacity, security, and resilience in Asia’s agri-food system.

👀 Use my discount code ‘BIO10’ to save 10%

Register here. See you there! 👋🏾

BETTER BIOECONOMY EXCLUSIVE

💬 My recent conversations with bioeconomy innovators

Founder of Media City Scientific, Katie Bashant Day: A Scientist-Founder’s Journey to Make Biotech Research Reliable and Ethical

Innovation Specialist at The Good Food Institute India, Devika Suresh: Laying the Foundation for Smart Protein Leadership in India

Biotech consultant and ex-CSO of Vow, James Ryall: Bridging Science and Business to Support Startups Using Biomanufacturing

Check out more conversations!

Enjoyed this issue? If it brought you value, please consider sharing it with a friend who might benefit, or making a small pledge to acknowledge the hours behind each piece. Thank you for reading and supporting my work!

Good day to you Eshan. Thanks for awesome issue #81! My, how time flies. It only seemed like yesterday when you published issue #80. It's great to see a record amount of money that came into the alt protein space in Europe this year. Hopefully we'll see many more euros invested in 2025. It was both exciting and sobering to read the excellent post about Revo Foods and Paleo working on creating products that will appeal more to our senses like real animal products. The sobering part is it will probably take five years to work it out. But I'm also optimistic that a future AI machine will be able to speed up the process. You're a very busy person Eshan! I used to publish a similar style newsletter for a large law firm i used to work at. I'm retired now. But I know how time consuming and labor intensive newsletters can be to create. So considering how fast time flies by, you might consider publishing your wonderful newsletters bi weekly. This will save you a lot of time and help prevent burn out. It's always an honor and privilege to receive and read your important newsletters. Take care my friend and do something extra special just for you today because you deserve it 👏 ❤️