Alt Protein Companies Raised $233M in Q3, Denmark's $73M Agrifood Tech Investment, and Beef Protein from Peas

Also: Hydrogen-oxidizing bacteria convert CO2 and nitrogen from wastewater streams to produce sustainable proteins

Hey, welcome to issue #79 of the Better Bioeconomy newsletter. Thanks for being here!

If you’re an agrifood tech founder, investor, or someone working on tech-based solutions for sustainable food systems, I’d love to connect. I started this newsletter to meet folks with similar interests, so feel free to reach out to chat on LinkedIn or hop on a call—I’m always happy to discuss ideas and opportunities! 🙂

Now, let’s dig into the latest developments in biotech-enabled agrifood businesses and breakthroughs! 🍽

BIO BUZZ

🇱🇺 Moolec Science gained ‘first‘ USDA approval for genetically engineered peas producing iron-rich beef protein using molecular farming

In the past 18 months, the Luxembourg-based company has secured three regulatory approvals for different genetically modified crops, including safflower oil enriched with nutrients and soybeans containing pork proteins.

The USDA’s Animal and Plant Health Inspection Service (APHIS) approved the genetically modified peas, confirming they pose no additional plant pest risk. However, the product will still need approval from the FDA before it can be commercialized as a plant-based protein source.

Moolec plans to launch genetically engineered peas (PEEA1) commercially in 2028. The peas, which contain beef proteins, offer consumers a novel plant-based iron-rich protein source.

Source: Green Queen

🇨🇿 Bene Meat Technologies produced its first cultivated burger, which will be priced the same as premium beef

The Czech startup is also progressing with its cultivated pet food venture, having already registered it as an EU feed material. Further “significant updates” on this product line are expected by late 2024 or early 2025.

The company avoids using controversial fetal bovine serum, instead developing its own proprietary growth media and equipment. This approach helps Bene Meat manage costs and ensure scalability for future large-scale production.

The startup is building a larger facility to produce around 200 tons of cultivated meat annually by 2025. However, products will still need to pass regulatory approvals in the EU before reaching consumers.

Source: Green Queen

🇸🇬 The APAC Society of Cellular Agriculture and Temasek Polytechnic signed an MoU to promote student engagement in cellular agriculture

The MoU marks the launch of the APAC-SCA (Student Chapter), Singapore’s ‘first’ student-led society dedicated to cellular agriculture. The collaboration specifically focuses on cultivating the next generation's interest in future food solutions like cultivated meat and seafood.

Key outcomes of this partnership include creating educational events and resources for students, focusing on raising awareness of alt proteins and developing short courses on novel food regulations.

Leaders from both organizations highlighted the importance of interdisciplinary collaboration to prepare students to contribute to the growing cellular agriculture industry, bridging the gap between education and industry needs.

Source: APAC-SCA

🇺🇸🇸🇬 The Better Meat Co received regulatory approval in Singapore for its Rhiza mycoprotein, paving the way for its international debut

Rhiza, made from Neurospora crassa, has historical significance in Asian cuisine and can be used in meat analogues, dairy products, and blended meat applications.

The Californian startup’s mycoprotein has a 50% protein content, a high digestibility score, and a rich nutrient profile that includes fiber and potassium. It is also low in cholesterol and saturated fat.

The product’s shelf-stability, texture improvements in blended meats, and B2B format (sold to food companies in granule form) make it a convenient and sustainable option. It is a functional ingredient for various food applications, including steaks, sausages, and deli products.

Source: Green Queen

🇩🇰 Denmark to invest 15 billion kroner by 2030 in R&D, focusing on climate-friendly agriculture and alt proteins to accelerate net zero goals

The agrifood sector is a major focus, accounting for 25% of Denmark’s greenhouse gas emissions. The government plans to cut emissions by 70% by 2030, partially through a carbon tax on meat and dairy production.

A sum of 500 million kroner ($73M) will fund innovations to lower the climate impact of food production, including techniques like soil carbon sequestration, biorefining, and new plant breeding methods.

The AgriFoodTure partnership, which involves 18 projects and 70 partners, is working on solutions across five areas, including alt proteins and sustainable animal food production, to achieve a climate-neutral food system.

Source: Green Queen

🇬🇧 The UK is poised to become a leader in alt proteins, but the country needs further action to solidify its leadership

A new briefing outlines a multi-stakeholder approach, stressing that advancing the alt protein industry requires ten tactical actions, including creating a comprehensive UK protein asset map, establishing incubator programs for small businesses, and conducting gap analyses in R&D facilities.

It suggests various initiatives to drive commercialization and future success, such as developing a database for protein structures, conducting lifecycle assessments of alt proteins, and creating educational content like videos and blogs.

Alt proteins must also be included in national dietary guidelines and industrial strategies, as well as a robust regulatory framework for safety, sustainability, and performance.

Source: Green Queen

⚡️ More buzzes

🇦🇹 Fermify achieved self-affirmed GRAS status for its precision-fermented casein after a comprehensive safety study. This milestone is crucial for introducing animal-free dairy products, including cheese, to the US market. (vegconomist)

🇫🇷 Ferments du Futur opened an innovation centre at the Paris-Saclay science and innovation cluster. The initiative is a public-private European partnership launched in December 2022, aimed at advancing sustainable and healthy food through fermentation technologies. (vegconomist)

BIO BUCKS

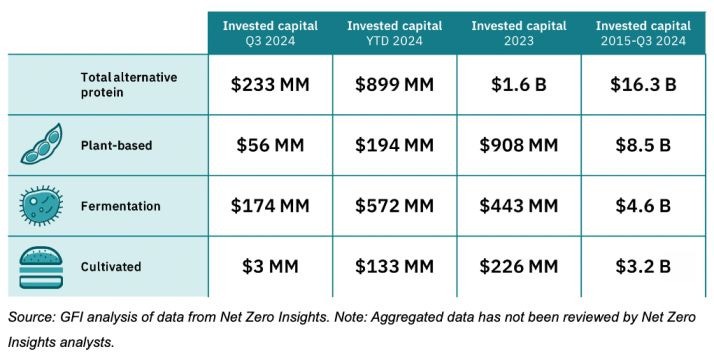

📈 Alt protein companies raised $233M in Q3 2024, bringing the total investment for the year to $899M

Plant-based companies raised $56M in Q3, with $194M raised year-to-date.

Fermentation companies secured the largest share of funding, with $174M raised in Q3 and $572M year-to-date.

Cultivated meat and seafood companies, raising only $3M in Q3 but still accumulated $133M year-to-date.

Source: GFI

🇮🇳 BioPrime raised $6M Series A funding to boost research on bio-based crop protection solutions

The funds will propel BioPrime’s research in bio-fungicides and bio-insecticides, aiming to offer sustainable crop protection solutions that reduce reliance on chemical inputs.

The Indian startup wants to expand its biostimulant product line into key agricultural markets such as North America, Southeast Asia, and Brazil. To support this international expansion, trials are currently being conducted in the US.

Central to BioPrime's innovation is its BioNexus technology. A collection of almost 18,000 strains has enabled the platform to identify more than 170 unique microbial strains. These strains speed up the development of bio-fungicides, bio-insecticides, and biostimulants.

💰 Key investors: Edaphon, Omnivore, and Inflexor Ventures

Source: iGrow News

🇩🇪 Infinite Roots and Hamburg University of Technology received €2.6M from the German government to upcycle whey for mycelium growth

The project's focus is to address the waste problem in the dairy industry by turning whey, a low-cost byproduct, into feedstock for growing mycelium.

The grant is part of the German government's national innovation support program, signalling strong public investment in sustainable food technologies. The Federal Office for Agriculture and Food oversees the project's progress as the implementing authority.

Infinite Roots, already experienced in using industry sidestreams like spent grain, sees whey as a promising alternative for producing mycelium. Whey could reduce costs while offering unique flavour profiles for mycelium-based products.

Source: Green Queen

🇨🇭 Sallea raised $2.6M in pre-seed funding to advance its plant-based scaffolding technology for cultivated meat

The Zurich-based startup’s scaffolds improve cultivated meats' texture and nutritional quality. Based on research from ETH Zurich, these scaffolds overcome the industry's current challenges, particularly in producing premium cuts like whole steaks and fillets.

Sallea's technology uses a unique method in which salt molds are 3D-printed and infiltrated with proteins. This allows them to create scaffolds that can make up to 90% of the end product, offering flexibility in shaping the nutritional profile and quality of the meat products.

The scaffolds can easily integrate into existing production systems without requiring additional investments or major changes, providing a cost-effective, plug-and-play solution for cultivated meat companies.

💰 Key investors: Founderful and Kost Capital

Source: vegconomist

🇺🇸 Tufts University Center for Cellular Agriculture gets $2.1M from The Healey-Driscoll administration and MassTech to create the FEAST center

The FEAST center will be a hub for advancing research in cultivated meat and other cell-based food products. It will be equipped with state-of-the-art tools and a test kitchen, which will enable academic and commercial entities to prototype and evaluate new products.

The initiative is expected to create 60 new jobs within the bioindustrial manufacturing sector, contributing to the growth of Massachusetts' biotech economy.

Aligned with BioMADE, a defence-sponsored manufacturing institute, the project is part of the M2I2 program, which supports innovation in hard tech by supporting collaborative efforts between businesses and academic institutions.

Source: vegconomist

💸 More bucks

🇯🇵 Japanese alt protein startups Agro Ludens, Deats Food Planning, and Fermenstation received grants from the Ministry of Agriculture, Forestry and Fisheries as part of the Small/Startup Business Innovation Research Program. (GFI Japan)

🇺🇸 Liberation Labs raised $3.4M to continue developing infrastructure for commercial-scale biomanufacturing. The $2M from Agronomics will be used to continue constructing the Richmond, Indiana Launch Facility. (Cell Base)

GEEK OUT

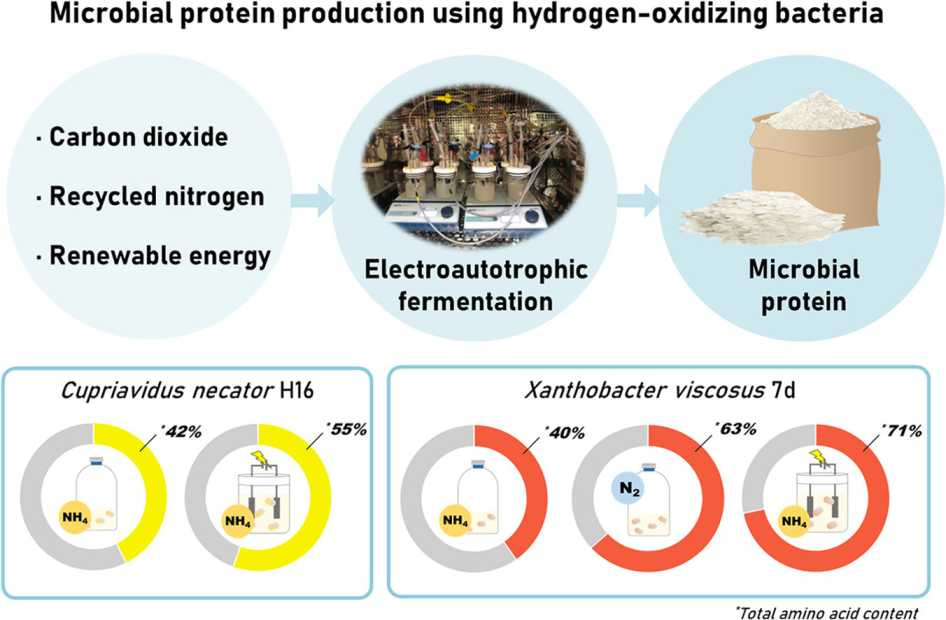

♻️ Hydrogen-oxidizing bacteria convert CO2 and nitrogen from wastewater streams to produce sustainable proteins

The hydrogen-oxidizing bacteria, Cupriavidus necator H16 and Xanthobacter viscosus 7d, produced high protein content—555 and 717 mg protein/g cell dry weight, respectively—in bioelectrochemical systems, making them competitive with fishmeal and soybean protein.

The study found that ammonium from wastewater streams is more effective for microbial protein production than urea or nitrate. This preference highlights the potential for repurposing wastewater in integrated bioelectrochemical systems.

This method reduces reliance on traditional agricultural practices by repurposing wastewater and CO2 for microbial protein production. It also mitigates issues like nitrogen runoff and eutrophication. The use of renewable energy and water electrolysis improves the overall environmental impact.

Source: ScienceDirect

🧬 CRISPR/Cas9 improved targeted knock-in efficiency in a key fungus for food and industrial enzyme production

CRISPR/Cas9 improved targeted knock-in transformation efficiency in Aspergillus oryzae, using microhomology-mediated end-joining (MMEJ) and single-strand annealing (SSA) repair pathways, reducing the need for host preparation and long homology templates.

The study showed a marked increase in successful transformants using CRISPR/Cas9 and short homology arms (15-50 bp). The number of transformants peaked with the 50 bp template, showing that precise knock-ins are achievable without extensive preparations.

The knock-in of the sodM promoter into the glaB gene resulted in higher expression levels of glucoamylase. This was confirmed through quantitative PCR and enzymatic assays.

Source: ScienceDirect

🐚 Microalgae bioconverts glucosamine, derived from chitin-based waste like crustacean shells, into valuable biomass

Chlorella vulgaris and Chlorella sorokiniana showed optimal growth when glucosamine was combined with glucose, reaching cell counts of up to 9.0 log/mL in 14 days. Enzymatic treatment further increased growth, with C. sorokiniana achieving a 3x growth improvement.

After laboratory adaptation, C. sorokiniana tolerated glucosamine concentrations 3x higher than the wild strains. This adaptation resulted in faster growth rates and doubled biomass recovery.

The research suggests that combining bioinformatics with laboratory evolution could lead to industrial-scale waste bioconversion into biomass. This process can potentially generate high volumes of alt protein from underutilized waste streams.

Source: ScienceDirect

🧲 Low-frequency alternating magnetic field increased mycelial biomass under submerged fermentation

Applying a 40 Gs low-frequency alternating magnetic field (LF-AMF) increased the production of extracellular polysaccharide (EPS) by 23.09% and mycelial biomass by 11.30%.

Optimal fermentation conditions were determined as 6.18 days at 28.28 °C, with a shaking speed of 149.04 r/min and an inoculum amount of 8.43%. Under these conditions, applying LF-AMF was most effective in improving fermentation outcomes.

LF-AMF treatment led to wrinkled and loose mycelium, potentially facilitating higher EPS production. LF-AMF also improved the antioxidant capacity of the EPS and increased ATPase activity, improving cell membrane permeability and metabolic exchange.

Source: PudMed

🧫 RNA virus-mediated delivery system for CRISPR/Cas9 allowed genome editing in pepper plants without genetic transformation

This transformation-free method is particularly important for pepper, which is traditionally challenging to genetically modify.

The process was highly efficient, with somatic editing frequencies as high as 75.73%, and 77.9% of plants regenerated from infected tissues showed heritable mutations. This offers a promising alternative for crops that resist conventional transformation techniques.

The method generated various plant phenotypes, including albino and mosaic plants, indicating different levels of gene editing. This technique opens the door for precise genome editing in other crops that are typically hard to transform.

Source: Wiley

POST & POD

🚀 We can't only focus on moonshots to push our food system in a better direction

Moonshot innovations such as cultivated meat and molecular farming aim to completely disrupt the food system with transformative technologies. However, we shouldn't overlook more immediate, incremental approaches, known as "chip shots," which work within existing systems to create value immediately.

While the potential upside of moonshots makes them worth pursuing, we should also focus on practical solutions that can have an impact today. A sustainable food system will require a mix of ambitious long-term projects and smaller, more attainable improvements.

An example of a chipshot he uses is Blue Stripes, which addresses 70% of cacao waste by creating valuable products. While this doesn't solve all the sustainability issues in the chocolate industry, it’s a meaningful step forward and highlights the importance of diverse solutions.

Source: Steve Molino

🎧 Owen Ensor on Meatly's cost structure, market strategy, and the future of pet food

APAC AGRI-FOOD INNOVATION SUMMIT

🤝 Meet 1000+ global leaders who are accelerating climate-adaptation strategies for food security in Asia

Better Bioeconomy is excited to be a media partner for the Asia-Pacific Agri-Food Innovation Summit at Marina Bay Sands on November 19-21!

As the anchor event of Singapore International Agri-Food Week (SIAW), in collaboration with Temasek, the Singapore Food Agency (SFA), and Enterprise Singapore (ESG), the Asia-Pacific Agri-Food Innovation Summit will bring together over 1000 global leaders to identify the strategic priorities as we build greater capacity, security, and resilience in Asia’s agri-food system.

👀 Use my discount code ‘BIO10’ to save 10%

Register here. See you there! 👋🏾

BETTER BIOECONOMY EXCLUSIVE

💬 My recent conversations with bioeconomy innovators

Founder of Media City Scientific, Katie Bashant Day: A Scientist-Founder’s Journey to Make Biotech Research Reliable and Ethical

Innovation Specialist at The Good Food Institute India, Devika Suresh: Laying the Foundation for Smart Protein Leadership in India

Biotech consultant and ex-CSO of Vow, James Ryall: Bridging Science and Business to Support Startups Using Biomanufacturing

Check out more conversations!

That’s a wrap. Thank you for taking the time to read this issue!

Are you new here?

Know anyone else who would dig this newsletter?

Hi Eshan, how are you doing on this wonderful day? I wish there was a 'love' button instead of a 'like' button for your fantastic newsletters ha ha 😂 😄.

My head is spinning in a nice way reading of all the developments you researched this week. They all are very cool.

I'll say my favorite development is from Sallea, because the public will want the texture of alt protein products to be very similar to its animal counterparts. I also like the podcast where pet food is discussed as potentially being sold commercially in Europe. Awesome!

If you currently do not have a Reddit sub dedicated to the alt protein space, I encourage you to create a Redfit sub. Of course, I will be a vocal community member, and as your sub grows, i would be honored to be a mod. Check it out ✔️

I know issue #78 took a lot of time, effort, expense to create. The community appreciates all your dedication and help. Have a fantastic week my friend ❤️