China's First Precision-Fermented Lactoferrin Approval, $73M for AI-Driven Protein Development, and 3D-Printed Cultivated Fish Fillet

Also: Alpine Bio harvested its first large-scale crop of soybeans containing casein proteins

Hey, welcome to issue #83 of the Better Bioeconomy newsletter. Thanks for being here!

I’m back after two whirlwind weeks, including Singapore's incredible Agri-Food Tech Week. It was an amazing experience to connect with some cool folks in the agrifood tech industry. A special shoutout to those who mentioned you read the newsletter—meeting you was such a joy! 🙂

If you’re an agrifood tech founder, investor, or someone working on tech-based solutions for sustainable food systems, I’d love to connect. I started this newsletter to meet folks with similar interests, so feel free to reach out to chat on LinkedIn or hop on a call—I’m always happy to discuss ideas and opportunities!

Let’s dig into the latest developments in biotech-enabled agrifood businesses and breakthroughs!

BIO BUZZ

🇦🇺🇨🇳 Australia's All G becomes the first company approved to sell precision-fermented bovine lactoferrin in China

Lactoferrin is a sought-after protein with functional benefits, especially in iron regulation, but its high cost and limited supply create opportunities for alt protein producers.

The Sydney-based startup claims to have developed the world's most efficient strain for bovine lactoferrin, achieving significantly lower production costs and scalability through global contract manufacturing facilities.

The company, which is targeting a product launch in the second half of 2025, is also advancing a bioidentical version of lactoferrin found in human breast milk, leveraging insights from its bovine lactoferrin research.

Source: Green Queen

🇰🇷🇩🇪 Infinite Roots partnered with Pulmuone to debut its mycelium-based meat analogues in South Korea

The products, featured in Pulmuone's Earth Diet line, include meatballs and hamburger steak. The products focus on the natural umami flavours of mycelium and mushrooms rather than mimicking meat, aligning with local tastes and sustainability goals.

Infinite Roots’ approval process highlights differences between regions: South Korea’s quicker, localized system versus the EU’s comprehensive but slower framework. This disparity encouraged the German company to prioritize Asian markets for initial commercial rollouts.

Pulmuone’s strong reputation in health-focused food and its $2.1B revenue (with a 135% profit growth in 2023) position it as a pivotal partner for Infinite Roots. Through its Earth Diet label, Pulmuone aims to broaden its meat alternative portfolio while aligning with its ESG goals.

Source: Green Queen

🇸🇬🇮🇱 Umami Bioworks and Steakholder Foods developed 3D-printed cultivated fish fillets after a two-year collaborative effort

The project, funded by the Singapore-Israel Industrial R&D (SIIRD) grant, seeks to address concerns surrounding ocean depletion and the sustainability of seafood production.

Partnering with Singapore’s National Additive Manufacturing Innovation Cluster (NAMIC), the collaboration demonstrated the feasibility of commercially viable 3D-printed cultivated fish prototypes representing various species.

By integrating 3D printing with cultivated seafood production, the partnership provides a scalable and ethical response to overfishing and marine degradation.

Source: Cell Base

🇰🇷 KoreaBIO, Bio-based Future Food Industry Committee, and GFI APAC signed an MoU to advance South Korea’s alt protein industry

The five-point MoU focuses on cross-industry learning, regulatory support, workforce training, and international outreach. The structured roadmap includes regular workshops, webinars, and knowledge exchanges to align efforts across stakeholders and advance protein innovation.

The yearlong partnership will strengthen South Korea's position in alt proteins, especially cultivated meat, which is expected to debut in the country soon. Industry members will meet quarterly to share data, market insights, and research, accelerating innovation and ecosystem development.

The MoU aims to improve regulatory conditions, creating a favourable environment for cultivated meat. It also seeks to connect South Korea’s alt protein ecosystem with global networks, leveraging GFI APAC’s extensive resources and relationships across its seven international offices.

Source: Green Queen

🇺🇸 Alpine Bio harvested its first large-scale crop of soybeans containing casein proteins in Nebraska, culminating seven years of R&D

The company uses molecular farming to produce casein, positioning it as a cost-effective alternative to precision fermentation. This approach addresses a critical industry need for cost-effective, animal-free casein for plant-based cheeses.

Transitioning to a B2B strategy, Alpine Bio aims to lock in large-scale partnerships and offtake agreements. This helps to scale, minimizes upfront capital requirements, and enables collaboration across the supply chain while keeping the option open to partner on consumer branding.

Alpine Bio has developed a closed-loop system for allergen management, using GPS tracking, geofencing, and industry collaboration to ensure precise traceability and compliance with FDA guidelines, setting new industry standards.

Source: AgFunder

🇬🇧 New Wave Biotech introduced an AI-driven simulation software to help alt protein companies scale production faster at lower costs

The software Bioprocess Foresight addresses critical challenges in scaling synbio technologies, where over 90% fail due to optimization difficulties and high costs, ranging between $10,000 and $100,000 per experiment.

The London-based startup’s new tool reduces the time for techno-economic analyses from months to hours and significantly cuts costs from $20,000–$40,000 to a monthly fee of £83 ($105).

With its intuitive design and comprehensive analysis tools, Bioprocess Foresight allows users to virtually test unlimited scenarios, predict economic and environmental outcomes, and streamline commercial scaling. This empowers companies to refine strategies and accelerate progress while minimizing risk.

Source: Green Queen

🇮🇱 Imagindairy received approval from Israel's Ministry of Health to sell its animal-free whey protein locally

This follows the US FDA's 'no further questions' approval in January, which validated the safety and potential of Imagindairy's protein and further solidified its credibility across global markets.

With ~65% representation in milk whey, beta-lactoglobulin is the focal point of Imagindairy’s product portfolio. Its advantages include superior nutrition and functionality, making it a valuable ingredient for enhancing food and beverage textures.

Beta-lactoglobulin is rich in essential and branched-chain amino acids like leucine, supports muscle synthesis, and provides functional benefits like heat tolerance, pH stability, and tastelessness.

Source: Green Queen

🇩🇪 ProteinDistillery is building a large-scale facility in Germany to produce 200 tonnes of Prew:tein derived from brewer's yeast annually

Prew:tein's protein content exceeds 75%, and its perfect digestibility score of 1.0 is comparable to that of egg and milk proteins like casein and whey. Its functionalities include acting as a binder, emulsifier, gelling agent, and foaming agent, making it a versatile ingredient for various food products.

The German startup’s ingredient addresses key challenges in the plant-based food industry by improving the realistic flavour and texture of products such as burgers, schnitzels, and cheeses.

Additionally, it stabilizes non-dairy whipping creams, enhances baked goods like muffins, and provides shelf-life improvements and thermal stability, all without relying on volatile egg supplies or synthetic additives.

Source: Green Queen

BIO BUCKS

🇳🇱 Cradle Bio raised $73M Series B to help scientists speed up protein development with AI in food, agriculture, and more

Cradle's AI platform accelerates protein engineering with 12x faster R&D cycles, significantly reducing costs and experimental requirements in therapeutics, agriculture, and food industries.

By building wet labs early, the Netherlands-based startup generated proprietary datasets to improve its AI models. The recent appointment of industry expert Sam Partovi and the expansion into US markets highlight the company’s focus on strengthening commercial and operational capabilities globally.

Having secured total funding of over $100M, Cradle has grown from just two paying customers at its Series A funding to 21 customers today, with 31 molecules in development. This includes partnerships with top pharmaceutical leaders like Johnson & Johnson and Novo Nordisk.

Source: SynBioBeta

🇺🇸 Ascribe Bioscience received funding from Source Agriculture Corp. to advance crop protection using soil microbiome-derived molecules

Ascribe's flagship product, Phytalix, acts as a plant vaccine that protects plant immune systems against pathogens. It is used on crops like corn, wheat, soy, rice, potatoes, and tomatoes.

With non-toxic, biodegradable, and non-GMO properties, Phytalix aligns with growers seeking sustainable farming practices, offering farmers and ecosystems a safer alternative to chemical pesticides.

Ascribe’s use of advanced metabolomics enables the development of stable, efficient, and field-ready biobased solutions. Unlike live-microbe treatments, their approach ensures consistency and cost-effectiveness, making it accessible for widespread agricultural use.

Source: iGrow News

GEEK ZONE

🔬 Designed synthetic microbial communities upcycled fermentation byproducts to increase production yields by over 100%

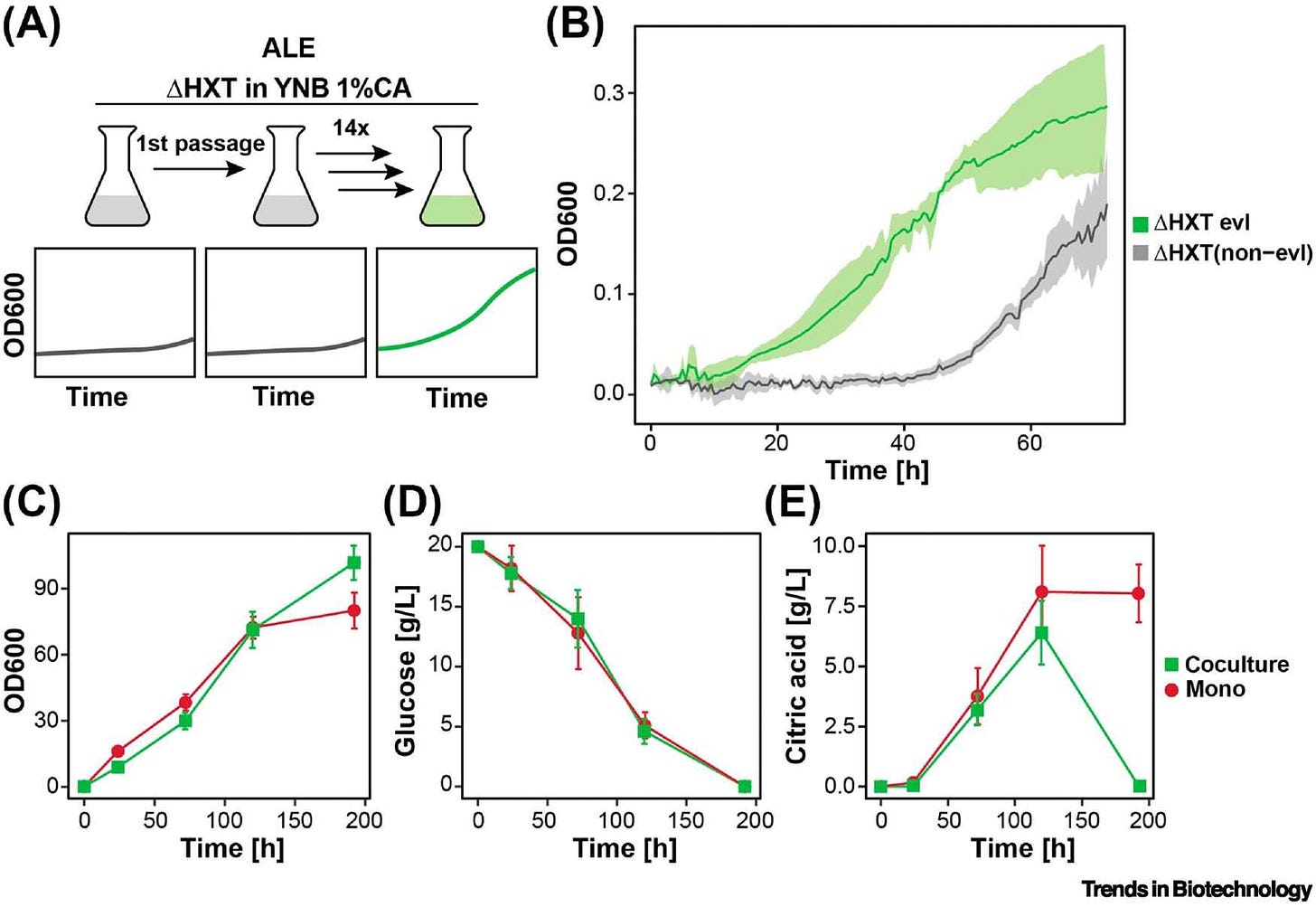

The study used adaptive laboratory evolution and metabolic engineering to create synthetic communities to tackle byproduct accumulation. A wild-type yeast (Yarrowia lipolytica) strain produces biomass and citric acid, while an engineered ‘upcycler’ strain converts citric acid into products like β-carotene.

The co-culture system showed a 135% increase in growth and a 104% increase in production compared to monoculture setups. It effectively used byproducts and yielded higher biomass, confirming the potential benefits of division of labour in microbial communities.

The scientists demonstrated this using β-carotene, with co-cultures yielding 998 mg/L in minimal media and 4101 mg/L in lignocellulosic hydrolysates, providing a cost-effective, sustainable bioproduction method.

Source: Cell Press

🍄 Fungal extract as a fetal bovine serum supplement reduced the cost of cultivated protein production

Grifola frondosa extract (GFE) was tested as a supplement to reduce the reliance on FBS. At a 12.5 μg/mL concentration, the extract showed enhanced cell proliferation and differentiation under low serum conditions (10% FBS), surpassing even 20% FBS medium.

Cells treated with GFE during proliferation and differentiation periods exhibited an almost 2 times increase in total protein production compared to cells in a standard 20% FBS medium.

Using GFE reduced the cost per mg of protein production by 3 times compared to conventional methods using 20% FBS. GFE, derived using hot water and ethanol extraction methods, proved effective and safe, aligning with the requirements for cultivated meat media.

Source: ScienceDirect

📈 Combined metabolic engineering and lipid droplet degradation increased vitamin A production in yeast by 10x

By addressing substrate-enzyme separation and storage bottlenecks in Saccharomyces cerevisiae (Brewer's yeast), the study improved Vitamin A production from 19.03 mg/L in shake flasks to 1100.83 mg/L in fed-batch fermentation.

The team evaluated 10 β-carotene monooxygenases (BCMOs), identifying marine bacterium-derived BCMO as the most efficient enzyme. Introducing two-phase fermentation with 10% dodecane and antioxidants helped stabilize Vitamin A, increasing its yield while reducing intracellular metabolic burden.

Sequential lipid droplet degradation improved enzyme-substrate interaction while overexpressing TGL3 and TGL4 under manganese-responsive promoters optimized β-carotene release. Further, upregulating oxygen-utilizing enzymes (VHb) addressed oxygen limitations, improving Vitamin A conversion rates.

Source: Microbial Cell Factories

🌾 Mycorrhizal fungi improved the growth and grain yield of wheat plants by mitigating the adverse effects of drought stress

Wheat plants experienced significant physiological and biochemical challenges under drought stress, including reduced chlorophyll a and b levels, which are essential for photosynthesis.

Arbuscular Mycorrhizal Fungi (AMF) enhanced wheat's resilience to drought by improving photosynthetic parameters (chlorophyll and Fv/Fm) and water retention capabilities (RWC%). Wheat inoculated with AMF exhibited higher grain weight and biological yield under drought than untreated stressed plants.

Proline accumulation, essential for osmoprotection under stress, was modulated by AMF, which ensured controlled levels in drought-stressed plants. Similarly, AMF inoculation reduced excessive phenolic compound levels while boosting beneficial soluble sugars, helping stress recovery.

Source: BMC Plant Biology

EAR FOOD

🎧 Cultivated meat’s past and the future: Insights from Eric Schulze, former FDA regulator and cultivated meat innovator

BETTER BIOECONOMY EXCLUSIVE

💬 My recent conversations with bioeconomy innovators

Founder of Media City Scientific, Katie Bashant Day: A Scientist-Founder’s Journey to Make Biotech Research Reliable and Ethical

Innovation Specialist at The Good Food Institute India, Devika Suresh: Laying the Foundation for Smart Protein Leadership in India

Biotech consultant and ex-CSO of Vow, James Ryall: Bridging Science and Business to Support Startups Using Biomanufacturing

Check out more conversations!

Enjoyed this issue? If it brought you value, please consider sharing it with a friend who might benefit, or making a small pledge to acknowledge the hours behind each piece. Thank you for reading and supporting my work!

Hi Eshan, thank you very much for this awesome issue #83. There are lots of great developments in the alt space. Glad you had a nice time at the convention. The community appreciates all your excellent work and efforts to help educate us. Have a wonderful week ❤️