US Bets Big on Precision Fermentation, $35M for Alt Chocolate, and First Cultivated Meat Application in Thailand

Also: Biokraft Foods hosted ‘India’s first’ formal tasting event for cultivated chicken meat

Hey, welcome to issue #84 of the Better Bioeconomy newsletter. Thanks for being here!

If you’re working on (bio)tech-based solutions for sustainable food systems, I’d love to connect. I started this newsletter to meet folks with similar interests, so feel free to reach out to chat on LinkedIn or hop on a call—I’m always happy to discuss ideas and opportunities! 🙂

Let’s dig into the latest developments in biotech-enabled agrifood businesses and breakthroughs!

BIO BUZZ

🇺🇸 Five of the nine final grants in the US Department of Defense’s biomanufacturing program went to precision fermentation startups

The US government is backing precision fermentation to strengthen national capacity in biomanufacturing. The technology is seen as pivotal for innovations in the food supply, fuel production, fitness-related biotech, and advanced materials for defence and industry.

Perfect Day, The Every Company, Cauldron, Liberation Labs, and Checkerspot are among the awardees of the Department of Defense’s Distributed Bioindustrial Manufacturing Program (DBIMP), with follow-on funding of up to $100M for building biomanufacturing plants in the US.

“The next industrial revolution will be a biomanufacturing revolution. DoD is keenly aware of that reality,” said Heidi Shyu, undersecretary of defence for research and engineering.

Source: Green Queen

🇹🇭 Aleph Farms filed the first-ever application for cultivated meat in Thailand, aiming for clearance by mid-2026

As the "Kitchen of the World," Thailand offers an ideal launchpad for the Israeli startup. Its culinary reputation, advanced food production ecosystem, and strategic access to Asian markets enhance the opportunity to integrate cultivated meat into mainstream cuisine.

Aleph Farms' Angus Petit Steak will debut under the "Aleph Cuts" brand. While the regulatory approval timeline remains tentative, the company anticipates an 18-month process.

Aleph Farms credits Thai Union, a key partner and investor, with helping it navigate Thailand's regulatory landscape. Their collaboration laid a strong foundation for Aleph Farms’ market entry, using local expertise and infrastructure for commercialization and tailored product integration.

Source: Green Queen

🇮🇳 Biokraft Foods hosted ‘India’s first’ formal tasting event for cultivated chicken meat

The event, held in Mumbai, brought together industry leaders and sustainability advocates, including representatives from PETA India, GFI India, CASMB, Brinc, YODA India, and the India Animal Fund.

Kamalnayan Tibrewal, the founder, expressed optimism about redefining meat production and commercializing cultivated meat in India, saying they are “working closely with the Indian regulatory body, FSSAI, and are optimistic about commercializing our product by next year.”

Using 3D bioprinting, Biokraft Foods focuses on producing sustainable, high-quality meat. The startup is supported by some of India’s leading incubators, including ICT Mumbai, SPTBI, and iCREATE.

Source: Kamalnayan Tibrewal

🇺🇸 Oobli received the FDA’s first “no questions” letter for its precision-fermented monellin sweet protein

It adds to Oobli’s existing regulatory approval for brazzein, further establishing the safety of sweet proteins as sugar alternatives in food and beverages. The California-based company claims to be the first company to create a platform with multiple FDA-approved sweet proteins.

Monellin is found in the serendipity berry, and brazzein in the Oubli plant. These proteins are naturally scarce and up to hundreds of times sweeter than sugar, providing potent alternatives for sugar reduction.

The precision fermentation production of Oobli’s sweet proteins reduces the environmental footprint of sweetener manufacturing, using less land, water, and carbon compared to traditional sugar production while delivering gut-friendly, low-glycemic products.

Source: vegconomist

🇩🇰 EU-funded project led by the Danish Technological Institute turns food waste into proteins and vitamins using fungi-based fermentation

The €7.5M Zest project, co-financed by the Circular Bio-Based Europe programme, promotes a circular economy by repurposing agricultural residues. It reduces waste, cuts greenhouse gas emissions, and uses less water than traditional protein production methods.

Custom-designed bioreactors and AI models optimize fermentation, allowing real-time adjustments to improve mycelium production. Data-driven insights help reduce waste, lower energy consumption, and ensure consistent product quality.

The resulting mycoproteins offer versatility for food, pet food, packaging, and cosmetics, with added benefits like high digestibility, a neutral flavour profile, and vitamins B12 and D.

Source: Green Queen

🇬🇧 The National Alternative Protein Innovation Centre formally launched at the University of Leeds to ‘transform the alternative protein landscape’

NAPIC, backed by £15 million from the BBSRC and Innovate UK, is co-led by the University of Leeds, the James Hutton Institute, the University of Sheffield, and Imperial College London. Its mission is to “transform the alternative protein landscape and contribute to a more sustainable future for our planet.”

The Centre's "PRODUCE, PROCESS, PERFORM, and PEOPLE" framework provides a comprehensive approach to addressing production, processing, and performance of alternative proteins while focusing on people-centric challenges like adoption and safety.

NAPIC joins a growing network of UK centres supported by public funding, including CARMA (£12M for cultivated meat), the Microbial Food Hub (£12M for fermentation-based alternatives), and the Bezos Center for Sustainable Protein, advancing research in cultivated meat, fermentation, and AI.

Source: vegconomist

🇰🇷🇮🇱 ToolGen and PlantArcBio partner to develop gene-edited soybeans with improved herbicide tolerance

By combining tolerance to two herbicide groups, the technology offers farmers greater flexibility and improved weed control efficiency. This could help reduce farming costs and improve crop protection.

ToolGen's expertise in CRISPR-Cas9 gene editing and PlantArcBio’s DIPPER™ platform for high-throughput gene discovery enables a non-GMO approach. This method improves crop traits, increases yields, and reduces environmental impact.

The Korea-Israel Industrial R&D Foundation (KORIL-RDF) supports the project with a $2.16 million budget, which signifies a strong international commitment to sustainable innovation.

Source: iGrow News

BIO BUCKS

🇩🇪 Planet A Foods raised $30M in Series B funding, marking the largest sum raised by a European alt chocolate producer to date

The funds will be used to expand its cocoa-free ChoViva brand globally. ChoViva is available in over 20 products and 42,000 stores across Germany, Austria, and Switzerland. It is set to debut in the UK and France in early 2025. Plans are also underway to bring the brand to the US and Asia in the near future.

With demand rising, the German company plans to ramp up capacity, scaling production from 2,000 to over 15,000 tonnes annually. Planet A Foods will use its strategic partnerships and facilities to meet this need.

The company is also advancing with its ChoViva Butter, a precision-fermented fat alternative made from agricultural sidestreams and local resources like beet sugar.

💰 Investors: Burda Principal Investments (co-lead), Zintinus (co-lead), AgriFoodTech Venture Alliance, Bayern Kapital, Cherry Ventures, and more.

Source: Green Queen

🇮🇱 Celleste closed a $4.5M seed round, including backing from Mondelēz VC arm to advance cell-based cocoa

Using plant cells grown in bioreactors, Celleste creates cocoa butter and powder identical to traditionally farmed cocoa. Provided regulatory hurdles in key markets like the US and EU are overcome, these products are anticipated to enter the market by 2027.

Mondelez International has made a second investment in Celleste Bio through its SnackFutures Ventures. This aligns with the company's strategy to mitigate the risks of fluctuating cocoa prices and supply shortages using innovative methods like cell-based cocoa.

Cocoa prices have more than doubled over the past year, climbing from below $4,500 per ton to current levels near $9,000 per ton. West African crop failures due to extreme weather and disease have strained global supplies, prompting chocolate manufacturers to explore non-traditional solutions.

💰 Other investors: Supply Change Capital (lead)

Source: Bloomberg

🇨🇱 Luyef Biotechnologies secured $1.25M in grants to advance cultivated meat production using upcycled agro-industrial byproducts

This includes $1 million from Chilean Economic Development Agency (CORFO) focusing on protein engineering for thermostable growth factors and $250,000 from GFI targeting cost-effective nutrient media.

TAMEE, the Chilean startup’s branded bovine myoglobin ingredient (heme), is designed to recreate the sensory experience of traditional meat by improving the flavour and appearance of plant-based and cultivated meat products.

Luyef is developing thermostable growth factors and nutrient-rich media supplements by repurposing agro-industrial by-products to reduce costs and reliance on animal-derived components.

Source: vegconomist

🇳🇱 Farmless received €1M grant from the European Regional Development Fund to develop its air-based fermentation technology

The Dutch startup will use the grant to optimize its fermentation technology at a First of a Kind (FOAK) facility. This follows its €4.8M funding in December last year to build a pilot brewery in Amsterdam.

Farmless’ air-based fermentation uses CO2, hydrogen, nitrogen, and renewable energy instead of sugar, producing proteins more efficiently than animal farming.

This production method is said to be carbon neutral, operates independently of agricultural conditions, and is highly efficient—requiring 5000 times less land than beef farming

Source: vegconomist

GEEK ZONE

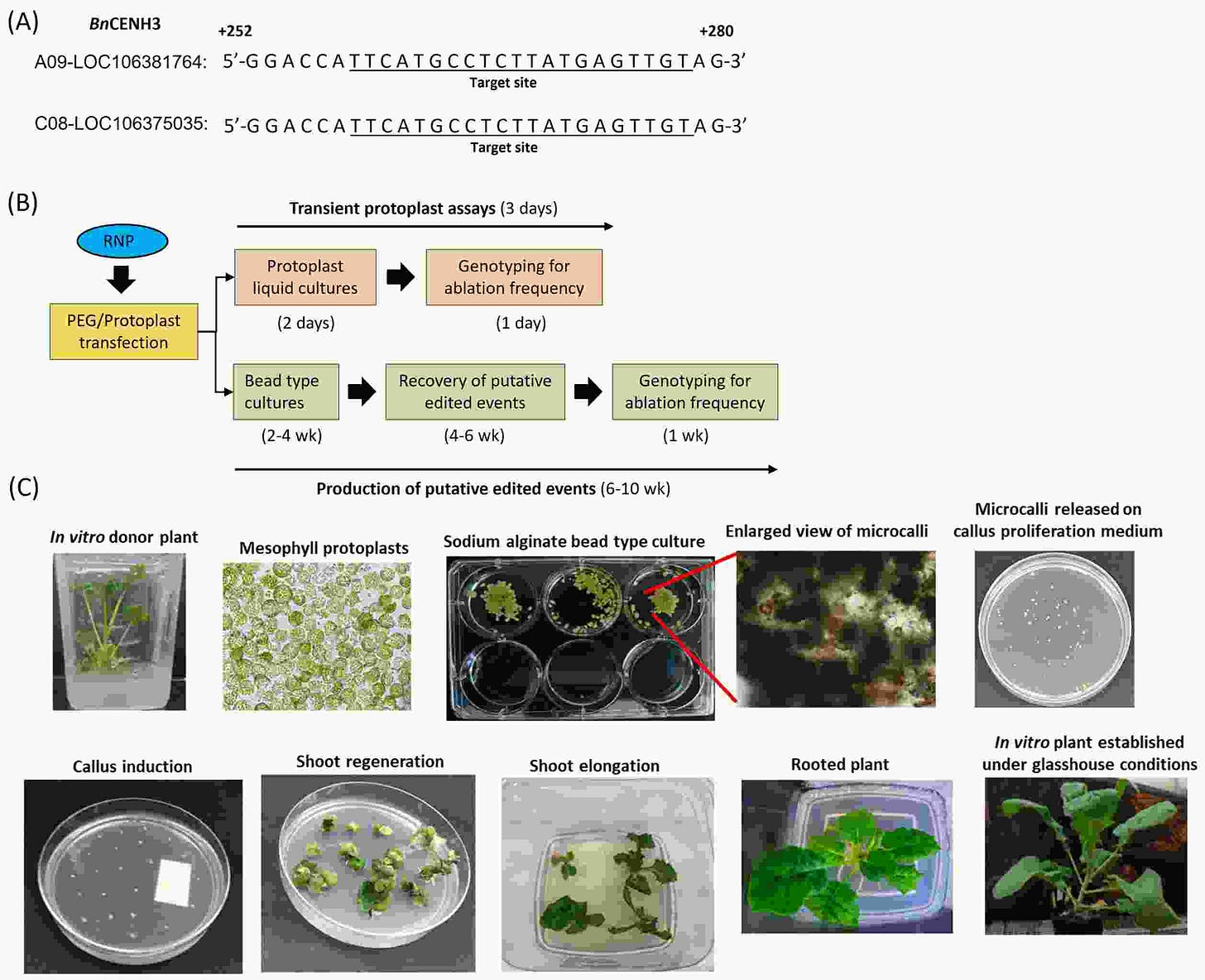

🌱 DNA-free genome editing using CRISPR–Cas9 RNPs for canola achieved 62% mutation efficiency, offering a GMO-free breeding tool

RNP (ribonucleoprotein)-based genome editing targets the CENH3 gene's 5′-UTR region in canola without introducing exogenous DNA. Of 525 regenerated shoots, 62% had at least one mutated allele, and 50% exhibited biallelic mutations.

The protocol, including polyethylene glycol (PEG)-mediated RNP delivery to protoplasts, simplifies the recovery of edited plants. Edited plants can be regenerated within 6–10 weeks, offering a practical solution for high-frequency editing, with 1200 T0 plants recovered in the study.

The DNA-free method reduces the regulatory challenges typically associated with GMO crops. This technique can potentially expedite canola breeding by enabling targeted trait improvements, such as yield and stress resistance, with a quicker and more reliable system.

Source: Frontiers in Plant Science

🔬 Effective RNA knockdown using CRISPR/Cas13 systems in plants could pave the way for crop improvement and viral resistance

The study introduced CRISPR/Cas13 systems as a precise RNA-targeting tool for plants, targeting endogenous genes and RNA viruses like the Tobacco Mosaic Virus (TMV). This approach offers a novel alternative to DNA-based editing methods such as CRISPR/Cas9.

Cas13x.1 and Cas13y.1 efficiently silenced two genes simultaneously, achieving editing efficiencies of up to 80%. The subtypes RfxCas13d, Cas13x, and Cas13y outperformed others in stability and specificity, offering potential for scalable applications in transcriptome editing.

Transgenic plants exhibited enhanced resistance to TMV with minimal oxidative stress and reduced viral accumulation. The RNA knockdown effects were inherited in the next generation, confirming the potential for heritable gene silencing.

Source: Genome Biology

POD & POST

🎧 Ferment’s Managing Partner Jason Kakoyiannis on building a venture studio focused on market-driven biotech solutions

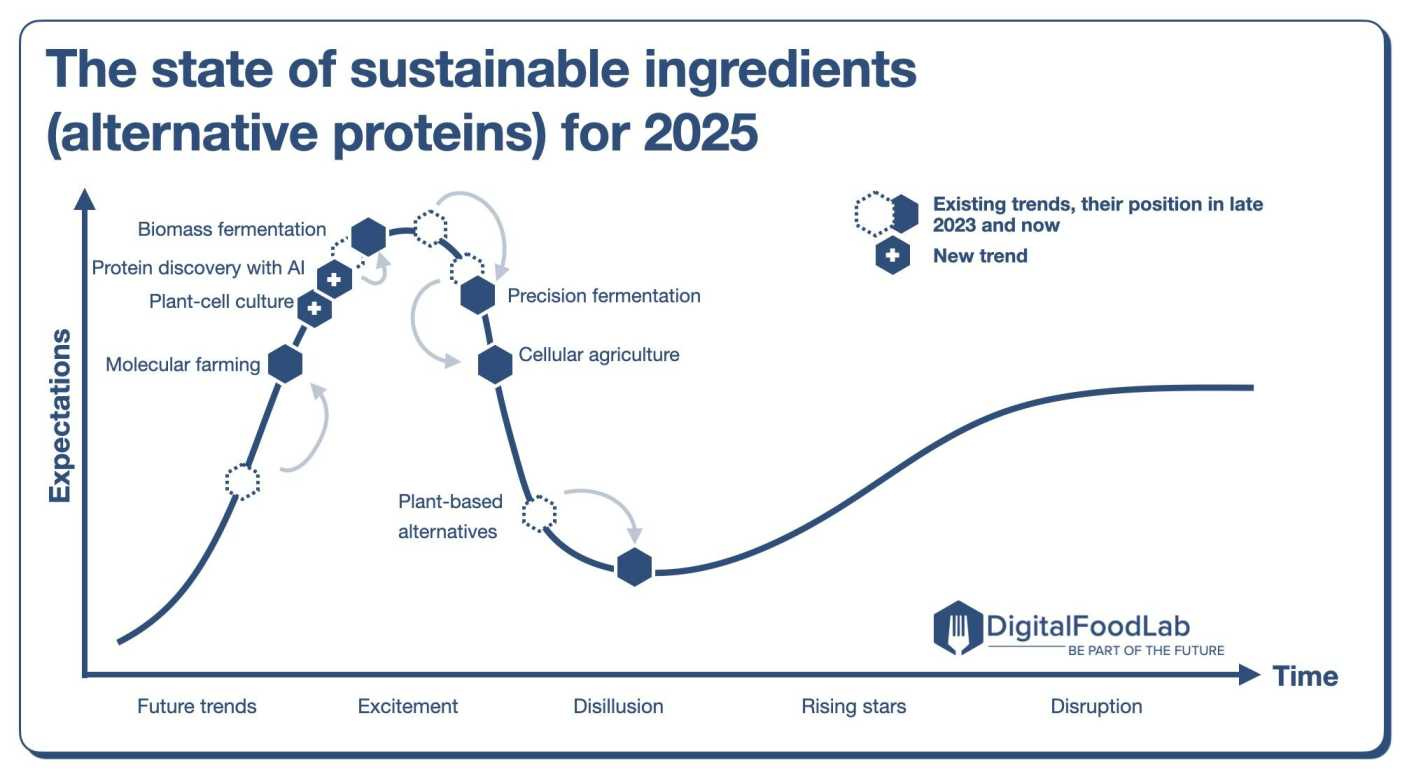

💡 DigitalFoodLab’s latest view on the trends shaping the future of ingredients

Precision and biomass fermentation: Precision fermentation is past its peak excitement, but scaling potential and niche focuses like "healthy ageing" show promise. Biomass fermentation is thriving in specific niches, such as CO2 conversion and solid-state methods.

Cellular agriculture: Facing challenges with bankruptcies and stalled expansion, the field is consolidating and experiencing a downturn.

Emerging trends: AI-driven protein discovery, plant-cell culture, and molecular farming are gaining traction. AI tools play a pivotal role in synthetic biology scaling, and plant-cell culture offers faster scalability and simpler regulatory pathways.

Source: Matthieu Vincent

BETTER BIOECONOMY EXCLUSIVE

💬 My recent conversations with bioeconomy innovators

Founder of Media City Scientific, Katie Bashant Day: A Scientist-Founder’s Journey to Make Biotech Research Reliable and Ethical

Innovation Specialist at The Good Food Institute India, Devika Suresh: Laying the Foundation for Smart Protein Leadership in India

Biotech consultant and ex-CSO of Vow, James Ryall: Bridging Science and Business to Support Startups Using Biomanufacturing

Check out more conversations!

Enjoyed this issue? If it brought you value, please consider sharing it with a friend who might benefit, or making a small pledge to acknowledge the hours behind each piece. Thank you for reading and supporting my work!

Hi Eshan, how are you doing on this very nice day? Thanks so much for excellent issue #84. All the developments look great, and my favorite story was the tasting event in India. I wish I was there! The community appreciates all the time and effort you put into making the world are better more sustainable place. Have a very nice and peaceful day 😊 ❤️