$50M for Climate-Smart Fertiliser, and Precision-Fermented Dairy Hits Shelves

Also: First cultivated pork dinner, next-gen breast milk fat, and farmers enter the cell-ag loop

Hey, welcome to Issue #116 of the Better Bioeconomy newsletter, a curated look at the latest in biotech for food and agriculture, covering commercial developments, funding rounds, scientific breakthroughs, and commentary. Thanks for being here! 👋🏾

Quick note: If you're an investor active in agrifood tech, I’d love to connect and exchange notes on what you’re seeing, what I’m picking up, and where things might be heading. If you’re up for a quick chat, grab a time here, or feel free to reach out at eshan@betterbite.vc if none of the times work.

In case you missed it, I recently wrote an article examining how ‘tricking’ cells into high production can transform biomanufacturing. Here’s the TL;DR of how Enduro’s “addicted” microbes could transform biomanufacturing:

📈 Longer runs, more output: Reactors stay productive up to 5× longer, compounding yield and reducing downtime.

💰 Economics tilt in your favour: Every cell pulls its weight, Enduro reports >30% higher titers, lowering COGS.

🏭 Predictable scale-up: Genetic stability narrows the lab-to-plant gap, reducing costly batch failures.

🦠 Tougher hosts, cheaper feeds: Enables wild strains and low-cost substrates (waste gases, residues) to stay on task.

♻️ Less waste, smaller footprint: More product per input means lower resource use and carbon impact.

🕹 Built-in process control: Cells act as live sensors, helping operators keep runs in the “green zone.”

As always, my understanding keeps evolving as I dig deeper. If you spot something I’ve missed or got wrong, let me know.

Alright, let’s get into it #116!

BIO BUZZ

Products, partnerships, and regulations

🇮🇱 Strauss Group set to introduce cow-free milk and cream cheese using Imagindairy’s precision-fermented whey protein

Strauss Group, which helped launch Imagindairy in 2020 through its incubator The Kitchen FoodTech Hub, is rolling out cow-free milk under Yotvata and cream cheese under Symphony. These will be the first precision-fermented dairy products available in Israeli supermarkets.

Imagindairy’s whey protein has a rich amino acid profile that supports muscle health, along with functional qualities like emulsification, gelling, and heat stability. It’s also free from lactose and cholesterol. With its 100,000-litre fermentation facility, the company claims it has been able to produce prototypes at the same price as conventional dairy, or even cheaper.

The new range is designed to meet the needs of vegans, flexitarians, and kosher consumers, while aligning with Strauss’s “Nourishing a Better Tomorrow” vision. Additional CowFree products are expected to follow.

Source: Green Queen

🤔 Thoughts:

The Strauss-Imagindairy story shows how Israel’s food tech ecosystem can work as a fast-track pipeline from startup idea to supermarket shelf. In this setup, a corporate-backed incubator like Strauss’s Kitchen FoodTech Hub helps launch a startup, which then grows with industry support and regulatory approval until the corporate itself becomes a big customer.

It’s a good example of how close collaboration between entrepreneurs, corporates, and regulators can speed up commercialisation and bridge the “valley of death” in food innovation. Israel’s wider approach, with the Israel Innovation Authority co-funding incubators, reinforces this alignment.

The result is a tight loop in which startups gain capital, expertise, and facilities, corporates secure early access to breakthroughs, and regulators provide relatively quick pathways for novel foods. Such an ecosystem has allowed Israel to build a strong track record in alt protein and continues to punch above its weight globally.

🇺🇸 Mission Barns became the world’s first company to sell cultivated pork, debuting its products at a San Francisco dinner

The dinner came just weeks after the USDA approved its cultivated pork fat, with Mission Barns organising three exclusive pop-up events for industry leaders and one sweepstakes winner.

Chef-owner Brandon Gillis created a special menu featuring Mission Barns’s fat, serving dishes like Sicilian-inspired meatballs with raisins and pine nuts, and Applewood-smoked bacon layered with the cultivated fat.

Mission Barns uses a hybrid approach, growing Yorkshire pig fat cells in patented bioreactors and blending them with plant proteins. Even at a low single-digit inclusion rate, the fat improves flavour and texture, allowing the products to perform on par with conventional meat in blind taste tests.

Source: Green Queen

🤔 Thoughts:

Mission Barns is using exclusive pop-up dinners as a practical go-to-market step. With funding for cultivated meat dropping sharply, companies need clear proof points to reassure investors and partners. These events let Mission Barns test how people respond to taste, pricing, and messaging in a controlled environment, while also producing data that supports licensing and B2B conversations.

The company’s focus on a proprietary bioreactor also shows where defensibility in cultivated meat may increasingly lie. Mission Barns says its design differs from pharma-style suspension tanks and is built for food-scale production. If it performs as intended, the system could support licensing opportunities.

Some non-food uses, such as cosmetics and biomaterials, may also be within reach. The broader signal is that cultivated meat firms are moving toward positioning themselves as platform companies with licensable infrastructure, a model that may be key to survival in today’s capital-constrained environment.

🇮🇳 ICL and BioPrime partner to launch soil and crop health solutions to India through BioPrime’s BioNexus microbial platform

This is the first time the BioNexus Library (home to 18,000 unique microbial strains) is being introduced via a global partner. With ICL’s strong presence and distribution network in India, farmers will now have access to consistent, precise, and biological solutions at scale.

Nutrient efficiency is a growing challenge. India relies on imports for much of its phosphate use (12% of global consumption), yet up to 85% of applied phosphorus gets locked in soils with iron and aluminium. At the same time, nearly half of Indian soils are zinc-deficient.

BioPrime’s BioNexus platform provides microbial strains capable of improving phosphorus efficiency 2-3x and solubilising 65-70% of zinc. This helps unlock otherwise inaccessible nutrients and reduces fertiliser wastage.

Source: AgroPages

🤔 Thoughts:

India’s agriculture faces a pronounced nutrient-use efficiency gap that reduces crop uptake and yield gains. This inefficiency also represents a huge economic drain, given the country’s heavy reliance on imported fertilisers.

Solutions that improve nutrient efficiency deliver value both through yield gains and input savings, by making fertilisers more effective and reducing waste. With subsidies costing the government over a trillion rupees annually, even modest efficiency gains could save billions. This creates a fast on-ramp for biological products, whose appeal lies in turning inefficiency directly into cost savings.

The payoff in India can be measured in fertiliser terms. For example, farmers may need less diammonium phosphate (DAP) if a phosphate-solubilising inoculant makes soil P more accessible. This framing aligns with national interests by easing subsidy pressures and reducing import dependence, while also strengthening farm-level economics.

🇨🇦 NRGene canola achieved 0% clubroot infection, marking the ‘first’ field demo of immunity-level resistance to the disease

In Saskatchewan trials, donor lines showed complete protection, hybrids carrying the trait saw just 0.2% infection, and stabilised breeding lines stayed below 1% across different environments. By contrast, current “resistant” commercial varieties failed with 74-85% infection rates under the same conditions.

The resistance was developed using genomics, AI, and precision molecular breeding methods such as gene pyramiding and introgression. This delivered durable, non-GMO protection that is adaptable across environments and positioned for smoother regulatory acceptance.

Compatible with commercial breeding pipelines, the technology reduces fungicide dependency, helps protect farmland, and supports farmer profitability. It also creates global licensing opportunities for seed companies under a royalty-based model.

Source: NRGene

🤔 Thoughts:

This sets a new benchmark for what “resistant” means in canola. Until now, hybrids have often been validated in greenhouse screens or limited field trials, but results like these put pressure on competitors to show that their solutions can hold up in highly infested real-world fields, such as those in Saskatchewan.

Over time, this could push breeding programs toward multi-gene, more durable resistance packages, since single-gene approaches may increasingly be considered insufficient.

Also, if clubroot control is embedded in the seed, the balance of value in disease management tilts further toward genetic traits (and the companies that own them) and away from external inputs like fungicides or soil treatments. In canola, where no fungicide is registered for clubroot because of cost and efficacy limitations, seed-based resistance already plays a central role.

🇳🇱 NoPalm Ingredients is scaling up its yeast-based palm oil alternatives with a factory at Nizo Food Research’s food innovation campus

This factory will consolidate all process steps under one roof to speed up production and cut costs. NoPalm uses a proprietary fermentation process with yeasts to convert local sidestreams like potato peels and whey permeate into “drop-in” palm oil replacements.

The startup will move from its 400-litre pilot fermentation line to producing hundreds of tonnes annually of yeast-derived oils, with a full-scale capacity beyond 1,200 tonnes per year.

Looking ahead, NoPalm aims to begin industrial-scale production in the second half of 2026, reaching technology readiness levels TRL 7–8, with additional scale-up planned for 2027 and 2028.

Source: Green Queen

🤔 Thoughts:

As food biotech scales, are hubs like Ede-Wageningen a preview of how sustainable ingredients will scale globally, concentrated in a few high-efficiency clusters rather than dispersed, one-off builds?

NoPalm Ingredients’ new demonstration plant at NIZO’s Food Innovation Campus in Ede suggests so. By tapping into an existing ecosystem with food-grade fermentation capacity, decades of operator know-how, and strong public investment, the company avoids the cost and risk of building from scratch.

This model helps startups move from pilot to commercial scale faster, with lower capital needs and reduced technical risk. Anchored by NIZO and Wageningen University & Research, the region shows how shared facilities and coordinated investment can make the path from lab to market more efficient.

🇺🇸 Yali Bio developed a precision-fermented breast milk fat with higher purity than what’s currently on the market

Using its recombinant yeast platform, the Californian startup produced OPO (Oleic-Palmitic-Oleic) with a 66-78% purity range, compared to enzymatic versions like Betapol (55-70%) and Infat (52-60%).

OPO mimics natural breast milk fat structure, supporting nutrient absorption, fat metabolism, and calcium uptake. These are essential for healthy growth, energy supply, and strong bone development during early infancy.

Supported by a $370k NIH grant, Yali Bio’s work highlights the role of precision fermentation in narrowing the gap between breast milk and formula. Its cost-efficient process is already drawing interest from formula makers in North America, Europe, and Asia.

Source: Green Queen

🤔 Thoughts:

Infant nutrition is moving toward evidence-led competition, with clinical validation emerging as a key differentiator for bioactive ingredients. Yali Bio’s work on a bioidentical human milk fat shows that claims will increasingly rest on measurable outcomes like fat absorption, calcium uptake, digestive comfort, and growth metrics, backed by peer-reviewed data.

Because infant formula faces stricter requirements than standard GRAS approvals, the bar is rising on regulatory rigour and study design. This could narrow the field to suppliers with strong clinical and regulatory capabilities, encourage closer partnerships with formula makers to generate data, and lead to adoption that is slower but more defensible. Cost and scalability still matter, but clinical performance could define who gets to market and at what price.

🇸🇬 Umami Bioworks registered two cultivated pet food ingredients with EU authorities, paving the way for Q2 2026 launch

The Singaporean startup1 has taken a key step toward commercialisation by registering two cultivated white fish ingredients under the EU Feed Materials Register (Category 10: fish and aquatic derivatives).

One ingredient is pure biomass, while the other is suspended in a nutrient broth. Both are designed to provide a sustainable source of omega-3 fatty acids, proteins, and key nutrients for the pet food sector.

The startup has also renewed its collaboration with California-based Friends & Family Pet Food Company. Based on Friends & Family's prior regulatory approval in Singapore, the company plans to roll out cultivated seafood-based pet food in Singapore, the UK, and the EU.

Source: Green Queen

BIO BUCKS

Funding, M&As, and grants

🇺🇸 Nitricity raised $50M Series B to meet strong demand for organic fertiliser from air, water, renewable energy, and upcycled almond shells

The new funding will support a plant in Delhi, California, with an 8,500-ton annual capacity. It’s expected to be up and running in early 2026, with production already locked in through binding agreements with local organic growers until 2028.

The California-based startup’s liquid fertiliser “Ash Tea” is made by combusting almond shells with renewable energy. The process produces a clear, reddish-orange liquid that runs smoothly through irrigation lines and avoids animal-based inputs such as manure or fish emulsions.

Field trials have shown 15-30% yield increases compared to conventional organic fertilisers. The fertiliser addresses common challenges like odour, spreading difficulties, and emitter clogging. It comes in two options: a neutralised version with added calcium and an acidic version that reduces the need for sulfur burners.

Investors: World Fund, Khosla Ventures, Chipotle’s Cultivate Next fund, Change Forces, Susquehanna Sustainable Investments, and more.

Source: AgFunder

🤔 Thoughts:

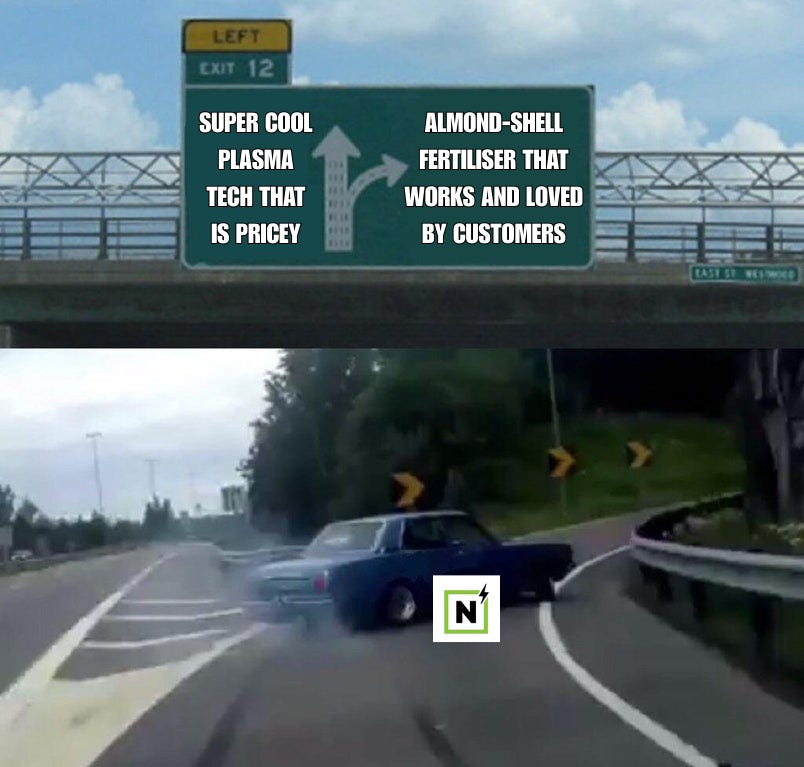

Nitricity’s move from its original “lightning-like” cold plasma nitrogen-fixation method toward a process based on combusting upcycled almond shells with renewable energy reflects a broader ag tech maturation. The plasma approach worked chemically, but as the team admitted, “the economics ultimately didn’t add up.”

This pivot is part of a broader industry shift where investors and partners prioritise technologies that prove they can scale cost-effectively, rather than chasing novelty for its own sake. That same pragmatism shows up in how Nitricity has designed its product.

By designing its liquid fertiliser to flow through standard drip and sprinkler fertigation systems, Nitricity lowers adoption barriers by slotting directly into farmers’ existing infrastructure. This “plug-and-play” design takes advantage of the widespread use of irrigation in speciality crops, where fertigation is already common. It’s a good example of how ag innovations gain traction fastest when they meet growers where they are.

🇨🇦 Protein Industries Canada invested C$6.6M in a C$32.5M project to develop fava bean and mycelium proteins from two local startups

The effort is led by startups Phytokana and Maia Farms, with the rest of the funding coming from industry partners. The goal is to strengthen Canada’s food security, broaden protein options, and support exports as global demand for sustainable, plant-based ingredients grows.

Phytokana, based in Alberta, will use its processing technology to turn novel fava bean varieties into protein concentrate, starch flour, and fava flour. These ingredients are intended for use in plant-based meats, dairy alternatives, and other functional foods.

Meanwhile, Vancouver’s Maia Farms will take Phytokana’s fava ingredients and convert them into mycelium proteins through biomass fermentation, producing sustainable, nutrient-rich ingredients for food manufacturers.

Source: Green Queen

🇳🇱 The Craft Consortium is building the world’s first cultivated meat farm in the Netherlands, co-funded with €2M grant from EIT Food

By positioning farmers at the core, the project decentralises cultivated meat production and provides farmers with opportunities to retrofit their stables for new food systems. This allows them to diversify income streams while ensuring cultivated meat complements livestock and crop farming.

The consortium brings together RespectFarms, Wageningen University, Mosa Meat, Aleph Farms, Multus, Kipster, and Royal Kuijpers, combining expertise across farming, science, biotech, and engineering.

The model enables slaughter-free meat production, with fewer cows needed and lower risks of livestock-related diseases. It’s a step toward a farming system where cellular and traditional methods coexist, producing local meat in a more resilient and sustainable way.

Source: Green Queen

🤔 Thoughts:

Cultivated meat’s cost depends on inputs like growth media (sugars, proteins, amino acids) and the energy needed for bioreactors. Bringing production onto farms could connect cell ag more directly with agricultural supply chains and local renewable energy. Since most media ingredients already come from agriculture, this shift could open new demand channels for crop outputs.

Over time, that might influence rotations or create niche markets (think corn farmers supplying dextrose or oilseed processors finding value in protein fractions). Some farm by-products could even find roles in media or scaffolding.

On-site renewables like solar, wind, or biogas add another layer of integration, turning farms into clean-energy hubs that support cultivation. If these linkages take hold, cultivated meat could become more locally grounded and resilient, while offering farmers additional income streams.

🇨🇭 FOOD FOUNDERS Studio raised CHF1.2M and launched its first startup

The Swiss venture studio’s first company tackles off-flavours in plant-based foods. The studio plans to raise CHF3M in total to build three startups over three years, adopting a focused, one-startup-at-a-time approach to lower risk and build B2B foodtech ventures with commercial potential.

Its mission is to unlock Europe’s underutilised food tech research, where just 1% of academic projects that reach market are food-related, by bridging the gap between academic incentives (publications, grants) and industry’s push for scalable solutions.

Researchers won’t have to choose between selling their IP or leaving academia. Instead, they can join new ventures as CTOs, consultants, or part-time collaborators, keeping flexibility while ensuring knowledge transfer.

Source: AgFunder

🤔 Thoughts:

Building one startup at a time, rather than pushing out cohorts, marks a clear bet on depth over breadth. Instead of playing a numbers game where only a few ventures survive, FOOD FOUNDERS’ studio model puts concentrated time and resources behind each company. This approach suggests that in science-heavy fields like food tech, hands-on support may deliver better outcomes than scale alone.

The studio’s market-first approach also tackles a familiar problem in food tech: investing in exciting science without clear demand. By validating markets early and engaging industry partners, it creates ventures pulled by real needs instead of pushed by tech for its own sake. This reflects a broader shift in food and deep tech toward demand-led innovation, and grounding startups in real traction from the start could help rebuild confidence in food tech as an investable space.

More bucks

🇮🇸 ORF Genetics raised €5M to scale production of specialised proteins for cultivated meat. The Icelandic company’s barley-driven Orfeus system uses molecular farming and hydroponic cultivation to produce recombinant proteins. (Green Queen)

🇮🇳 Biokraft Foods raised ₹2 crore pre-seed funding from GVFL to advance cultivated meat in India. The Mumbai-based startup uses 3D bioprinting and tissue engineering to create cultivated chicken.

EAR FOOD

Podcast episode of the week

🎙 The three overlapping circles that guide future agriscience innovation

Innovation decisions in agriscience are guided by three overlapping priorities: solving farmer challenges, leveraging the current state of science, and ensuring a return on investment. A new technology moves forward only when all three align.

The biggest barrier to delivering new tools to the farm is regulation. Traits and crop protection products can take a decade or more to clear approval, often due to inconsistent or politicised systems. A more harmonised, science-based approach would accelerate innovation and broaden access.

There’s growing interest in diversifying beyond corn and soybeans, but economics and regulatory hurdles have kept alternatives out of reach. Advances in gene editing and modern breeding could make new crops more viable, reducing farmers' risks, improving soil health, and opening new markets.

Guests: Farmer/podcaster Corey Hillebo and Corteva CTO Sam Eathington

Podcast: Agriscience Explained

APAC AGRI-FOOD INNOVATION SUMMIT

Don’t miss your chance to attend the Asia-Pacific Agri-Food Innovation Summit and get 10% OFF with my network code. From breakthrough food systems to next-gen agri-tech, this is where Asia’s innovation leaders connect, collaborate, and create impact.

👀 Use my exclusive partner code for 10% OFF your pass: BIO10

Learn more: https://tinyurl.com/s9k5x3d7

See you in Nov!

GOT A MINUTE?

If you found value in this newsletter, consider sharing it with a friend who might benefit! Or, if someone forwarded this to you, consider subscribing.

This newsletter is free, but if you'd like to support the time and effort behind each issue, a small pledge is always appreciated.

Thank you, and have a great day!

Disclaimer: The views and opinions expressed in this newsletter are my own and do not necessarily reflect those of my employer, affiliates, or any organisations I am associated with.

Disclaimer: Better Bite Ventures, where I work, is an investor of Umami Bioworks.

Hi Eshan! How are you doing on this very nice day? Thank you very much for taking the considerable time and effort to create excellent newsletter issue #116. I love reading your awesome newsletters because you help me understand some challenges and issues in the bio protein space. My biggest concern is factory farming and your section on the Netherlands 🇳🇱 helping farmers re-tool their stables and transition to fewer animals was eye opening. Step by step we'll get there! You are doing a fantastic job of helping educate your subs, who in turn, share your newsletters and information with friends, family, and most important, social media networks. I've posting many time on various Reddit subs information that I've learned from you. So you reach millions of people, really. Keep up the marvelous job Eshan. You're doing the Lord's work my friend. Have a wonderful week 👍❤️

Title: Why We Need to Know What Are the World’s Top 10 Plants and Trees Which Capture the Most CO 2/Acre/Time Period

Given the fact that the world has not been timely mitigating Climate Change and has also allocated much of its public and private funding to extremely expensive CO 2 Capture Solutions, there is an even greater need for cost-effective, acreage and time-efficient, nature-based CO 2 Capture Solutions.

Our approach, using my patented CRBBP Process, is to deploy, on underutilized and/or challenged land, an extraordinarily Cost-Effective and Acreage and Time-Efficient, Nature-Based Solution, which maximizes the potential of Photosynthesis, a process which is among the least costly ways to capture CO 2, at $35/Ton, but we also sequester the captured Carbon in a variety of Climate-Smart Bio-Products, creating an expanding Bio-Economy and new Bio-Economy jobs.

However, to maximize these impacts, we and the world need to know what are the top 10 plants and trees which will capture the most CO 2/Acre/5,10 & 15-Year Periods.

So, I hope you will join me in urging that governments, universities and research institutions quickly, possibly using AI, conduct the credible analyses required.

Regards,

Joe

Joseph J. James, President

Agri-Tech Producers LLC

116 Wildewood Club Court

Columbia, SC 29223

Cell: (803) 413-6801

Email: josephjjames@bellsouth.net

Website: https://www.agri-techproducers.biz