Cultivated Chicken for $11/lb, 400% More Fruit From Gene-Edited Tomato, and Bioelectric Seed Growth

Also: A new bacterial species could improve crop productivity in saline soils

Hey, welcome to issue #82 of the Better Bioeconomy newsletter. Thanks for being here!

If you’re an agrifood tech founder, investor, or someone working on tech-based solutions for sustainable food systems, I’d love to connect. I started this newsletter to meet folks with similar interests, so feel free to reach out to chat on LinkedIn or hop on a call—I’m always happy to discuss ideas and opportunities! 🙂

Now, let’s dig into the latest developments in biotech-enabled agrifood businesses and breakthroughs!

BIO BUZZ

🍗 SuperMeat’s new insights reveal a path to producing cultivated chicken at $11.8 per pound

The cultivated meat market is often questioned about its scalability and cost-effectiveness. SuperMeat’s latest report and video offers detailed insights on the technical metrics, KPIs, and overall process efficiency, arguing that there is a clear path to commercial success for cultivated meat.

The Israel-based company uses embryonic avian stem cells that naturally replicate and differentiate, enabling efficient production of muscle and fat cells without scaffolding. It aims to scale up from 10 to 25,000-liter bioreactors.

Based on a 10-liter prototype and calculations for a 25,000-liter scale, SuperMeat estimates production costs of $11.8-$13.4/lb, provided certain media costs and cell densities. This price range aligns with premium poultry pricing in the US.

Source: AgFunder

🇯🇵 Norwegian Mycelium (NoMy) launched a subsidiary in Japan to produce sustainable proteins using food industry sidestreams

NoMy Japan partnered with Nippon Beet Sugar Manufacturing Co. (Nitten), the country’s largest sugar beet manufacturer, to use sugar beet byproducts to produce filamentous fungal protein.

The Oslo-based startup’s new service, MycoPrime, combines AI and data science to improve the efficiency of upcycling efforts. It helps industry partners maximize their use of agricultural byproducts to create valuable food products.

The startup is conducting a feasibility study with Hokuren, a major agricultural company, to explore broader applications of their technology.

Source: Green Queen

🍅 Phytoform’s gene-edited tomato could produce 400% more fruit in a vertical farm

The UK-based startup has developed a mini version of the Ailsa Craig tomato plant, which is one-sixth the size of a conventional plant but produces 5x more fruit.

Phytoform can fit 50-100 mini tomato plants per m2 in a vertical farm setup, enabling 3 growing cycles per year compared to the single annual cycle of traditional tomato plants.

Phytoform’s tomato plant produces 1 kg of fruit from a 300 g plant, with harvests reaching up to 150–300 kg/m2, a 180-400% yield increase over conventional systems. This yield boost could help vertical farming become more profitable.

Source: AgFunder

🇩🇪 Ohly launched yeast-based bionutrient line supporting fermentation processes for alt protein production

The newly introduced nutrients offer a balanced profile of essential compounds—including amino acids, vitamins, and nucleotides—designed to adapt to the unique requirements of each production process.

This launch is part of the expansion of Ohly’s X-SEED portfolio, with new products X-SEED KAT Advanced, X-SEED KAT Plus, and X-SEED Carbo Peptone refined through pilot studies and customer trials by Ohly’s R&D team.

The German company’s expanded portfolio includes solutions like OHLY FLAV-R-MAX for flavor enhancement and NEIVA to support immune health, complemented by a new facility to scale up production for the alt protein sector.

Source: vegconomist

🔬 Jellatech opened a 9,000 ft2 facility in North Carolina for advancing cell-based collagen research and production for pre-clinical trials

The US biotech company’s new facility is equipped with advanced bioreactors and labs to support high-quality, sustainable bioidentical Type 1 collagen production.

Jellatech’s new plant will be GLP (Good Laboratory Practice)-certified by 2026, supporting collaborative R&D with industry leaders for biostimulatory and regenerative healthcare solutions.

Founded in 2020, Jellatech uses cellular agriculture to produce bio-identical collagen from bovine, porcine, and human cells. It raised $2M in 2021, and closed a $3.5M seed round in 2023.

Source: vegconomist

💡 8 learnings from Future of Protein Production Amsterdam 2024: Enabling tech, low-cost media, and consumer focus

The alt protein industry is moving from consumer products toward process innovations, focusing on scaling technology to reduce production costs. Eg: Revo Foods is working on proving its 3D printing technology in the market before shifting to a B2B approach.

Companies like Nutreco and MarraBio are developing low-cost media for cellular agriculture, anticipating large-scale demands by 2040, while FlyBlast uses insect-based insulin alternatives to drive down costs in cultivated meat.

Consumers prioritize taste, health, and cost over environmental impact. Insights from Sodexo Netherlands suggest that highlighting these personal benefits could help wider adoption of alt proteins, reinforcing the need for companies to reframe marketing messages to focus on direct benefits to consumers.

Source: Green Queen

BIO BUCKS

🇺🇸 BioMADE invested $26.9M in 17 projects supporting US biomanufacturing and workforce development

The 17 projects range from producing biodegradable plastics, upcycling waste—including food waste—to creating certification programs for bioeconomy careers, all aimed at scaling and commercializing bio-based products in the US.

These projects involve 30 organizations from 18 states across sectors like private industry, nonprofits, and academia.

By producing sustainable materials and components domestically, these projects support job growth, reduce reliance on foreign imports, and aim to establish a resilient supply chain for bio-based products.

Source: BioMade

⚡️ Rainstick secured funding from Better Bite Ventures to improve seed growth with bioelectric innovation and Indigenous wisdom

Fertilizers are essential for feeding billions but contribute up to 5% of global emissions. Rainstick’s cutting-edge approach uses electric field treatments on seeds to increase yield while reducing fertilizer reliance.

The Australian startup’s Variable Electric Field Treatment (VEFT™) mimics natural lightning effects to promote seed growth. It uses bioelectric principles to adjust desired seed traits through biological and electrochemical changes.

Co-founders Darryl Lyons, informed by indigenous practices like the 'chuggera' (rain stick), partnered with biotech and AI expert Mic Black to combine ancient wisdom with modern technology for agricultural solutions.

Source: Better Bite Ventures1

🌽 Aphea.Bio received €1.9M from VLAIO to expand its maize-targeted biostimulant into the US and Brazilian markets

The biostimulant INITIΛ improves maize yields by promoting early plant vigor, boosting root biomass, and improving nutrient uptake efficiency (notably nitrogen and phosphorus). This results in better grain yields and reduced reliance on synthetic fertilizers.

The funding allows the Belgium-based company to trial and adapt INITIΛ in high-potential markets like the US and Brazil.

Beyond maize, Aphea Bio plans to expand INITIΛ’s use to other staple crops, broad-acre fields, and fruit and vegetable markets.

Source: iGrow News

💰 More bucks

🧫 Global Agri-Food Advancement Partnership (GAAP) invested in Argentina-based ERGO Bioscience, which produces animal proteins through plant cell cultivation. ERGO's North American expansion will begin with setting up R&D facilities in Saskatoon. (Business Wire)

GEEK ZONE

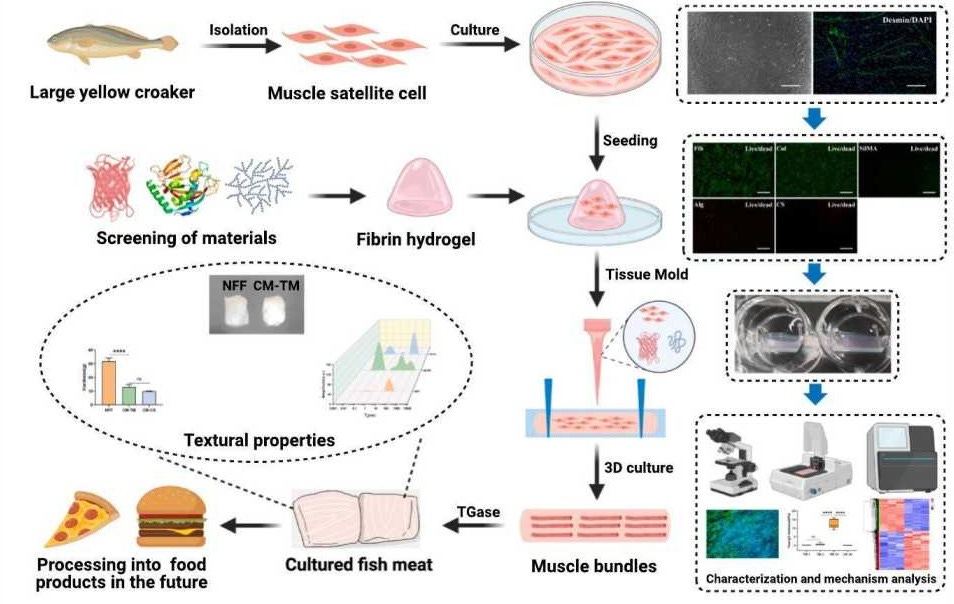

🐟 Researchers created an easy-to-use tissue culture method to produce cultivated fish meat with highly aligned muscle fibres

The study highlights fibrin hydrogels as a viable scaffold material. They allow fish cells to proliferate rapidly and differentiate effectively, leading to the rapid formation of muscle tissue that mimics natural fish.

Transcriptome analysis revealed that tissue mold positively impacts myoblast differentiation and myotube alignment, increasing the myotube fusion index to 72.65%.

Cultivated fish developed with this method closely mimics the sensory qualities of natural fish meat. However, nutritional differences—such as specific fatty acid profiles—indicate room for further refinement.

Source: ScienceDirect

🦠 A novel pathway used by a thermophilic bacterium could simplify the genetic transfer of nitrogen fixation to crops

Researchers discovered that Roseiflexus sp., a thermophilic bacterium, uses a novel pathway to synthesize the FeMo-cofactor needed for nitrogenase activity without the NifEN proteins, which are traditionally considered essential.

Unlike conventional nitrogenase, Roseiflexus’s nitrogenase assembly uses only NifH, NifB, and apo-NifDK proteins. This simplicity could enable nitrogen fixation capabilities in non-diazotrophic plants, suggesting a possible future in engineering crops for atmospheric nitrogen fixation.

Experimental work showed that the Roseiflexus nitrogenase is functional in nitrogen and acetylene reduction, with activity optimized at high temperatures, reflecting its thermophilic origin. These features support its stability and efficiency in different conditions from standard nitrogenases.

Source: PNAS

🧪 A new bacterial species could serve as a bioinoculant to improve crop productivity in saline soils

The new species Algoriphagus halophytocola, isolated from Salicornia europaea, was characterized as a plant growth-promoting bacterium (PGPB). The study suggests its role could be significant in saline agriculture, where salt stress often hinders plant development.

The bacterium’s production of indole-3-acetic acid (IAA) and proline supports plant growth under salt stress, with observed effects on Arabidopsis thaliana in experiments showing improved root and shoot growth and higher chlorophyll content in treated plants.

The bacterium’s genome revealed features like quorum sensing and glycosyltransferase enzymes, which facilitate its symbiotic relationships and stress resistance.

Source: Frontiers

🔬 Microbial lysates offer a low-cost serum replacement in cellular agriculture media formulation

The study (preprint) introduces a low-cost, microbial lysate-based alternative (VN40) for FBS in cultivated meat, using Vibrio natriegens lysates to successfully support the growth and differentiation of bovine muscle cells.

Screening various microbial lysates identified V. natriegens as optimal, allowing long-term cell growth and maintaining myogenicity. The lysate-based VN40 medium led to faster cell doubling times than the Beefy 9 serum-free medium.

VN40 enabled cost-effective cell culture, achieving a 99.2% cost reduction per liter compared to FBS. VN40 media cost $2/L versus $264/L for FBS.

Source: bioRxiv

EAR FOOD

🎧 Ark Biotech’s Yossi Quint on using computational bioprocessing to advance the cultivated meat industry

APAC AGRI-FOOD INNOVATION SUMMIT

🤝 Meet 1000+ global leaders who are accelerating climate-adaptation strategies for food security in Asia

Better Bioeconomy is excited to be a media partner for the Asia-Pacific Agri-Food Innovation Summit at Marina Bay Sands on November 19-21!

As the anchor event of Singapore International Agri-Food Week, in collaboration with Temasek, the Singapore Food Agency, and Enterprise Singapore, the Asia-Pacific Agri-Food Innovation Summit will bring together over 1000 global leaders to identify the strategic priorities as we build greater capacity, security, and resilience in Asia’s agri-food system.

👀 Use my discount code ‘BIO10’ to save 10%

Register here. See you soon! 👋🏾

BETTER BIOECONOMY EXCLUSIVE

💬 My recent conversations with bioeconomy innovators

Founder of Media City Scientific, Katie Bashant Day: A Scientist-Founder’s Journey to Make Biotech Research Reliable and Ethical

Innovation Specialist at The Good Food Institute India, Devika Suresh: Laying the Foundation for Smart Protein Leadership in India

Biotech consultant and ex-CSO of Vow, James Ryall: Bridging Science and Business to Support Startups Using Biomanufacturing

Check out more conversations!

Enjoyed this issue? If it brought you value, please consider sharing it with a friend who might benefit, or making a small pledge to acknowledge the hours behind each piece. Thank you for reading and supporting my work!

Disclaimer: At the time of writing, I am employed as the analyst at Better Bite Ventures

Good day to you Eshan. How are you doing on this very nice day? Thanks so much for excellent issue #82. It's wonderful to read that companies all over the world are making steady progress in the alt protein space. There is growing synergy happening! My favorite article this week is your first story on how SuperMeat is working on producing alt protein chicken at roughly $14 per pound. But my excitement is tempered that it probably will take 5 years to bring it to market? But that's not toooo long in the big view of things. Finally, if you would like me to send a message to Better Bite Ventures letting them know how valuable and educational your informative newsletters are, just let me know. Heck it might be good to put in your personelle file. Have a very nice and peaceful week my friend ✌️