UK Fast-Tracks Cultivated Meat Approval, World's Largest 3D-Printed Food Factory, and 4X Heme Growth in Engineered Yeast

Also: Cultivated meat could contribute €85B annually to the EU's economy and generate 90,000 new jobs by 2050

Hey, welcome to issue #78 of the Better Bioeconomy newsletter. Thanks for being here!

Here’s my favourite quote that I came across while working on this week’s issue:

“I think we’ll start coming out of this downturn in the next 18 months to two years. Right now we’ve got corporates who are running around saying, ‘Hey, I can invest in these companies and get a lot of value for my money.’ And they’re right. They can. There’s a lot of really good companies that need cash right now. So now is a great time to make the investment.”

- Andrew Ive, founder of Big Idea Ventures

By the way, if you’re an agrifood tech founder, investor, or someone working on tech-based solutions for sustainable food systems, I’d love to connect! I started this newsletter to meet folks with similar interests, so feel free to reach out to chat on LinkedIn or hop on a call—I’m always happy to discuss ideas and opportunities. 🙂

Now, let’s dig into the latest developments in biotech-enabled agrifood businesses and breakthroughs! 🍽

BIO BUZZ

🖨 Revo Foods opened the ‘world’s largest’ factory for 3D-printed food, producing 60 tonnes of product per month

The facility's first product is an updated 3D-printed mycelium-based salmon fillet using Revo’s 3D Structuring technology. This method integrates fat and protein to replicate meat textures, producing fillets with a realistic taste and feel, especially when cooked.

The Austrian startup’s technology uses mild production conditions that preserve the nutritional integrity of the food, unlike traditional methods that degrade nutrients due to high temperatures or pressure.

Revo plans to expand by offering its 3D food-printing technology to other businesses to create new revenue opportunities. Partnerships with other businesses are expected to be announced in early 2025.

Source: Green Queen

🐟 Umami Bioworks is launching operations in the UK to address overfishing and dwindling fish stocks, starting with white fish

To advance the commercialization of their cultivated seafood products, the Singapore-based startup is partnering with UCL and Imperial College, tapping into the UK's strong biotech expertise.

With 70% of seafood imported and local fishing industries under pressure from overfishing and post-Brexit regulatory challenges, the UK seafood market is at a tipping point.

The UK government’s initiative to create Europe's first regulatory sandbox for cultivated meat (more on this news later) strongly indicates its commitment to supporting food innovation, providing a favourable environment for companies like Umami Bioworks1.

Source: Cell Base

🐾 Bene Meat Technologies developed a cell bank with over 5,000 high-quality primary cell samples for cultivated meat production

The cell bank was created to ensure optimal preservation, maintaining the purity and stability of the cells. It also includes secure systems to protect against emergencies.

In May, the Czech startup introduced the ‘EU's first’ cultivated pet food product at the Interzoo Fair and is working on scaling production to bring it to market by the end of the year.

BMT is expanding into the USA by submitting a safety dossier to the FDA to introduce its cultivated pet food product to the US market.

Source: Cultivated X

💪🏾 Food tech startups must focus on adding significant value and solving real customer problems to survive the current downturn

Andrew Ive, founder of Big Idea Ventures, stressed that food tech companies should prioritize core business fundamentals, ensuring they solve meaningful problems and deliver value to customers. Startups that can do these will have a better chance of weathering the current economic downturn.

The funding downcycle is likely to last another 18 months to two years. During this period, corporations are capitalizing on undervalued startups, but once the market recovers, innovators will have greater access to capital and control.

While corporations take advantage of investment opportunities during the downturn, the market will "flip" in two years, putting startups back in the driver’s seat and shifting corporate expectations.

Source: AgFunder

🇪🇺 Cultivated meat could contribute €85B annually to the EU's economy and generate 90,000 new jobs by 2050

A new report says cultivated meat could bring between €20-85B annually to the EU's economy, directly impacting the cultivated meat sector and induced spending. This could result in 25,000-90,000 new highly skilled jobs by 2050.

Cultivated meat has climate benefits, too. It can significantly reduce the environmental footprint, potentially avoiding 3.5 gigatonnes of emissions by 2050. It could also cut EU agricultural land use by up to one-third and decrease water consumption by 7%.

However, investment and regulatory support are needed to achieve this. The EU needs to allocate €500M annually, particularly toward R&D and infrastructure. Public funding, better regulatory processes, and increased consumer awareness are key to making cultivated meat a mainstream product by mid-century.

Source: Green Queen

GEEK OUT

📈 Metabolic engineering of yeast for fermentative heme production achieves a nearly fourfold increase

The metabolic engineering of yeast (Saccharomyces cerevisiae) increased heme production by 3.9x compared to the wild-type strain. This addressed bottlenecks in the heme biosynthesis pathway, like enzyme limitations and competition for precursors.

The most successful strain included HMX1 gene disruption to prevent heme degradation and overexpression of PUG1 to improve protoporphyrin IX (a heme precursor) uptake, producing 28 mg/L of heme in glucose-limited fed-batch fermentation.

Although yeast-based systems show promise, they still lag behind bacterial systems in heme production capacity. The best bacterial strains can produce up to 1.03 g/L of heme. This suggests that further optimization and possibly hybrid approaches may be needed for industrial-scale production.

Source: Biotechnology Journal

🔬 Scientists developed a novel Japanese eel myoblast cell line for cultivated meat application

Satellite cells were isolated from Japanese eel (Anguilla japonica) muscle tissue to create cultivated eel meat, but initial myoblast populations declined over time, giving way to fibroblast-like cells.

RNA-Seq and RT-qPCR showed significant downregulation of key myoblast markers like pax7a and myoD, which indicated the loss of myoblastic traits and a shift towards non-muscle cell populations.

Through single-cell cloning, a stable myoblast cell line, JEM1129, was developed. It shows strong expression of myoblast markers and enhanced myotube formation in differentiation media.

Source: ScienceDirect

🌱 Plant and yeast-based hydrolysates offer a promising low-cost alternative to expensive cell culture media

NMR analysis revealed considerable differences in metabolite composition across nine hydrolysate products. Yeast extract had the highest concentration of metabolites (43%), while soy hydrolysates showed much lower levels (14%)

Despite concerns about batch variability, the study found that this inconsistency is largely confined to a small subset of metabolites, such as nucleotides (notably in yeast products) and glycerol (in cotton hydrolysates).

Yeast extract showed a high concentration and variety of nutrients, making it a strong candidate for improving cell culture media formulations for cultivated meat production.

Source: ScienceDirect

😋 Spirulina protein-based emulsion gels delivered better juiciness in meat analogues than conventional fats like palm oil

Spirulina platensis-based emulsion gels (SPP, SPP-XG, Bigel) outperform traditional fats in terms of juiciness while achieving comparable cooking loss and shrinkage rates in meat analogues. They prove effective across different cooking methods, offering a more sustainable alternative to conventional fats.

The Spirulina-based meat analogues maintained texture and moisture under various cooking methods. Steaming led to higher water retention, while frying caused peripheral moisture migration due to temperature and humidity effects.

At 30% fat content, there is a correlation between increased cooking loss and shrinkage. Among the fat analogues, SPP-XG, with added xanthan gum, exhibited the best water-holding capacity, reducing cooking loss and shrinkage compared to other formulations.

Source: ScienceDirect

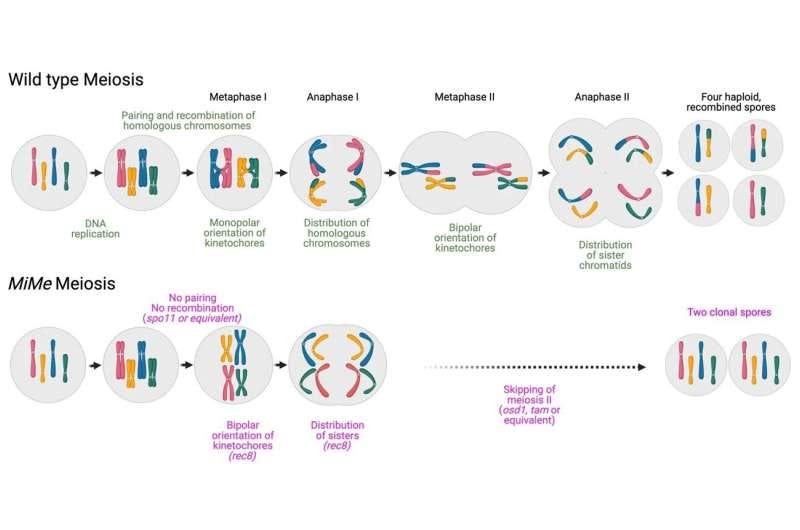

🧬 New technique enables the creation of genetically identical hybrid plants

Hybrid crops such as maize can yield 30% more than their inbred counterparts. However, due to sexual reproduction and genetic recombination, these benefits disappear in the second generation, causing a loss of uniformity and yield gains.

Scientists are working to propagate hybrids asexually through seeds by bypassing meiosis and fertilization. This method would ensure that the hybrid's advantageous traits are passed down unchanged, reducing seed production costs and enabling the development of more hybrid varieties.

The MiMe process (mitosis instead of meiosis) has been applied to crops like rice and tomatoes. This technique allows scientists to create plants with complete genetic information from both parents, leading to "super-hybrids" with improved traits like drought resistance and larger fruits.

Source: Phys.org

🍚 Protein engineering improved the amino acid content and stress resilience in rice

Rice, a staple food in many regions, lacks essential amino acids like lysine. Addressing this deficiency could improve nutrition in populations dependent on rice.

By mutating the dihydrodipicolinate synthase (DHDPS) enzyme to prevent feedback inhibition from lysine, researchers increased the lysine content of rice grains by 29% and the protein content by 15%.

The engineered rice plants had higher lysine and showed increased stress tolerance, better antioxidant levels, more efficient photosynthesis, and improved grain yield.

Source: Oxford Academic

BIO BUCKS

🇬🇧 UK government granted £1.6M to the Food Standards Agency to create a regulatory "sandbox" to fast-track approval for cultivated meat

These sandboxes are controlled testing environments where regulations can be adapted to fast-evolving technologies like cultivated meat. They aim to cut the red tape and improve collaboration among startups, regulators, and researchers.

In addition to this initiative, a new Regulatory Innovation Office will collaborate with multiple government departments to streamline introducing new technologies.

The cultivated meat sandbox is designed to lower the financial barrier to regulatory approval, cutting the typical cost range of £350,000-£500,000 per product. Starting in February, it will run for two years and collect scientific data to ensure these products' safety and proper labelling.

Source: Green Queen

🍫 California Cultured received a “significant” investment from Sparkalis, the venture arm of Puratos, a major player in bakery and chocolate

The startup produces high-flavanol cocoa using plant cell culture technology. It is positioned to help meet the rising global demand for cocoa through high-flavanol cocoa, a healthier product, and aims to reduce reliance on traditional cocoa farming methods.

The startup's partnerships, including one with Japanese giant Meiji, will help expand its reach. Construction on a new 12,000 sq ft production facility is expected to be completed by mid-December.

CEO Alan Perlstein emphasized the strategic value of the partnership with Puratos' Sparkalis, noting their alignment in biomanufacturing and plans to scale up operations. Further technological innovations in cocoa are on the horizon.

Source: AgFunder

🤔 Is the venture capital model right for agritech?

Venture capital (VC) remains relevant in agritech due to the scalability provided by technology. While agriculture as a sector typically involves long-term investments with lower returns, the tech side allows for scalable solutions, making it attractive to VCs.

However, agritech requires patience due to farmers' slow adoption rates and the biological complexities of agriculture, making it difficult for VCs focused on short-term returns.

It’s noted that agritech lacks enough acquirers to scale innovations compared to healthcare industries, and the industry ecosystem is not yet mature enough to support large-scale investments.

Source: AgFunder

POST & POD

💰 Smart ways to save money when setting up your first biotech lab space

When launching a biotech company, founders have various options for laboratory space. Many start in academic labs or commercial co-working spaces. Some even use more unconventional spaces like attics for initial proof-of-concept work.

Katie chose to custom-build their lab instead of using a shared space, drawing on their experience from helping to set up four early-stage R&D labs. This background gave her a clear idea of her lab needs and allowed her to create an efficient, purpose-built environment.

Cost-saving tips include using a plastic bin with sous vide stick for a water bath, 3D printing lab parts, buying second-hand equipment online, and getting food-grade CO2 from a homebrew store. Instead of a $30,000 high-end freezer, buy a smaller -80°C freezer for under $2,000.

Source: Katie Bashant Day

🎧 Jeff Tripician, CEO of Meatable, shares insights into his 40-year career in agriculture and the necessity of cultivated meat

APAC AGRI-FOOD INNOVATION SUMMIT

🤝 Meet 1000+ global leaders who are accelerating climate-adaptation strategies for food security in Asia

Better Bioeconomy is excited to be a media partner for the Asia-Pacific Agri-Food Innovation Summit at Marina Bay Sands on November 19-21!

As the anchor event of Singapore International Agri-Food Week (SIAW), in collaboration with Temasek, the Singapore Food Agency (SFA), and Enterprise Singapore (ESG), the Asia-Pacific Agri-Food Innovation Summit will bring together over 1000 global leaders to identify the strategic priorities as we build greater capacity, security, and resilience in Asia’s agri-food system.

👀 Use my discount code ‘BIO10’ to save 10%

Register here. See you there! 👋🏾

BETTER BIOECONOMY EXCLUSIVE

💬 My recent conversations with bioeconomy innovators

Innovation Specialist at The Good Food Institute India, Devika Suresh: Laying the Foundation for Smart Protein Leadership in India

Biotech consultant and ex-CSO of Vow, James Ryall: Bridging Science and Business to Support Startups Using Biomanufacturing

Co-founder of Synonym, Joshua Lachter: Financing and Developing Infrastructure for the Bioeconomy

Check out more conversations!

That’s a wrap. Thank you for taking the time to read this issue!

Are you new here?

Know anyone else who would dig this newsletter?

Disclaimer: Better Bite Ventures, where I work, is an investor of Umami Bioworks.

Wow, thanks for this fantastic issue #78. I'm amazed at every one of your information packed newsletters. So many wonderful developments going on in the alt protein space. It warms my heart. May you make all the riches you desire. Have a very nice and peaceful week ❤️